First metal additively manufactured part to land on the moon

April 11, 2019

The additively manufactured aluminium engine mount (Courtesy RUAG Space)

The first metal additively manufactured part is set to land on the moon today, April 11, 2019. Developed by RUAG Space, Zurich, Switzerland, the aluminium engine mount is fitted on the main engine of the ‘Beresheet’ lunar lander, developed by non-profit organisation SpaceIL, Israel.

“Our 3D part will support landing and lift off of the spacecraft on the moon,” explained Peter Guggenbach, RUAG Space CEO. Since 2014, the company has developed a number of space components by AM. For the production of this part, it contracted Morf3D, El Segundo, California, USA, a provider of Additive Manufacturing solutions with a focus on the aerospace industry.

“With 3D printing, our customers profit from a quicker and more cost-efficient production,” stated Guggenbach, adding that “weight reduction is a decisive factor in the space industry. The lighter the satellite, the lower the costs. Every kilogram less saves money, since less energy is needed for sending the satellite into orbit.”

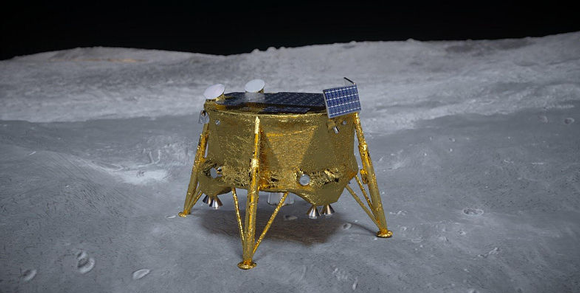

Beresheet, SpaceIL’s lunar lander, will have travelled two months through space before landing on the surface of the moon (Courtesy RUAG Space)

SpaceIL’s mission represents the first non-governmental landing on the moon. Its total budget is estimated at $95 million, provided mainly by philanthropists and the Israel Space Agency (ISA). Today, Beresheet will land on the lunar surface and begin sending photos and videos back to Earth, as well as data about the moon’s magnetic field.