Farsoon and Siemens accelerate software integration for industrial Additive Manufacturing

June 18, 2020

China’s Farsoon Technologies, Changsha, and Siemens China, Beijing, have announced that the first Farsoon Additive Manufacturing machine installed with Siemens NX software has now started beta-testing at a customer site.

After establishing a framework for integrated industrial solutions for Additive Manufacturing last September during the 21st China International Industry Fair (CIIF), Siemens and Farsoon’s R&D teams have been working to push the technology integration.

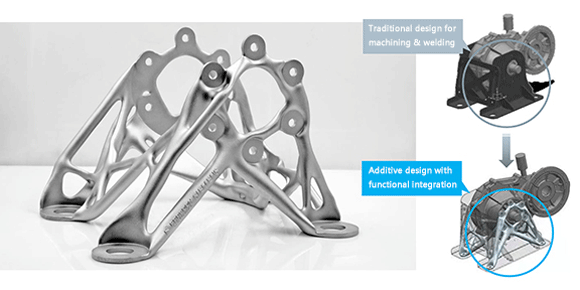

The goal of this collaboration was the implementation of Siemens’ end-to-end software and ‘Digital Twin’ solutions on all Farsoon metal and plastic open platform industrial AM systems.

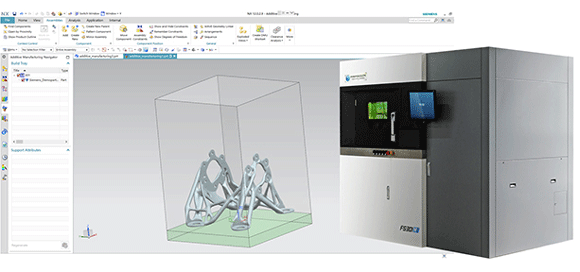

Siemens NX software integrates key functions including design, topology optimisation, CAE verification, process simulation, build evaluation and scan-path planning. With clear focus on industrial AM and “Open for industry” philosophy, Farsoon is reported to have established an increasing industrial customer base amongst aerospace, automotive, tooling, and large-scale manufacturing users.

Hope Hou, General Manager of Farsoon Technologies, announced the first hardware integration during his presentation at the Siemens booth during Formnext 2019. “The industrial control components from Siemens Digital Factory Solution have been applied to Farsoon’s latest metal laser sintering system FS301M, offering high-quality AM solutions to industrial users,” stated Hou.

A further presentation by Xia Weihua, Technical Director of Digital Industries Siemens Greater China, titled ‘NX Design-Simulation Platform and Case Studies’ will take place at the Farsoon booth (E5-H07) during TCT Asia 2020, July 8–10, Shanghai, China.