Expansion at VBN Components following fully subscribed funding round

March 10, 2021

Despite the challenges caused by the coronavirus pandemic (COVID-19), hard material specialists VBN Components AB, Uppsala, Sweden, has continued with its planned expansion to meet the growing interest and demand in its additively manufactured Vibenite products. The company has now expanded sales channels with new distributors and sales representatives in Asia, Europe and North America.

Thanks in part to the completion of its latest funding round, the company plans to move to larger premises this spring in order to accommodate its growing workforce. The additional space will also allow for investments in production equipment, thus increasing its range of services.

“The fully-subscribed funding round shows that our owners strongly believe in our global vision, which makes me proud, and is very motivating,” stated Johan Bäckström, CEO. “Our expansion of both sales channels and sales worldwide have begun to yield results, which shows that our offer is right on time.”

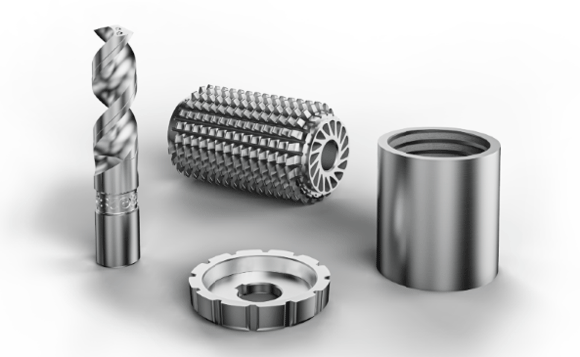

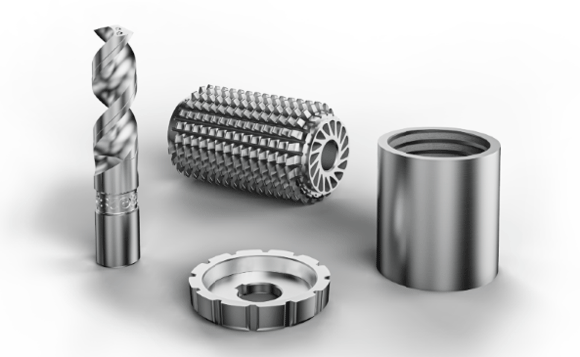

VBN Components develops metal alloys with extreme wear and heat resistance, including alloys such as Vibenite 290, said to be the world’s hardest, commercially available steel, and Vibenite 480, an additively manufactured cemented carbide.