ExOne launches new additively manufactured tooling range

September 7, 2021

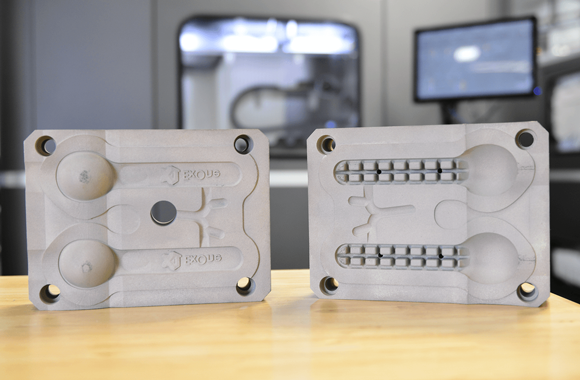

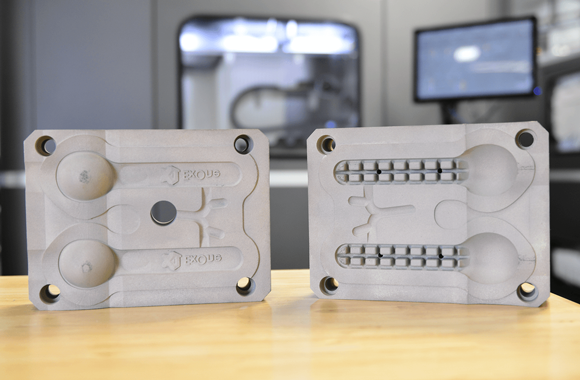

The ExOne Company, North Huntingdon, Pennsylvania, USA, has launched X1 Tooling, a new range of industrial-grade Binder Jetting (BJT) additively manufactured tooling for the final production of metal, plastic and composite parts.

The company is expanding its tooling business following the previously announced acquisition of assets from Freshmade 3D, as well as successful testing of new additively manufactured metal tooling with global customers.

“Today’s launch of the X1 Tooling portfolio is the direct result of strong customer demand for tooling options that speed up delivery times and bring tooling closer to the point of final production, wherever that is for them,” stated John Hartner, ExOne’s CEO.

Manufacturers can purchase X1 Tooling products directly from ExOne through the company’s ExOne Adoption Centers. The company is offering six additively manufactured metal or sand-based products, aimed at various end-use applications.

The X1 MetalTool option has passed preliminary tests to replace standard steel or aluminum tooling for plastic injection molding, blow molding, and other plastic and foam forming applications. It is available in 420i, a highly durable steel-bronze matrix, as well as 316L stainless steel, M2 tool steel, and more.

Tooling produced from X1 MetalTool can be machined, acid etched and polished to a diamond finish, and is said to be ideal for complex inserts. In addition to plastic forming applications, X1 MetalTool can also be used to directly additively manufacture end-of-arm tooling, and rugged perishable or consumable cutting tools in a variety of metals, including tool steels.

ExOne explained that its X1 DieMold is still in development, but rugged die moulds additively manufactured in H13 tool steel are currently fast-tracked with several global manufacturers after passing proof of concept tests.

Other sand-based tooling options include X1 SandCast, X1 ThermoForm, X1 Layup and X1 Washout.

Several ExOne customers are reported to be already using the tooling range, including Celwise AB, which is using X1 MetalTool 316L for an innovative moulded fibre application. North American Mold is also using X1 MetalTool 316L and 420i for both injection moulding and blow moulding applications, and is to serve as an ongoing development partner on these applications.

Hartner added, “As the COVID pandemic has continued disrupting supply chains, we’ve had more and more manufacturers ask us: Can you 3D print tooling? Today, we’d like the market to know that the answer is yes – we can help de-risk your supply chains and make them more sustainable, with less shipping and other forms of waste. Our new tooling portfolio is a grand slam of fast and affordable new tooling options for manufacturers.”

The X1 Tooling products will be showcased when ExOne exhibits at Rapid+TCT 2021 which takes place in Chicago, Illinois, USA, on September 13–15, 2022.