Equispheres metal powder outperforms in testing for aerospace, space & defence

October 3, 2019

Equispheres, Ottawa, Ontario, Canada, has released results from the first phase of powder testing by a facility specialising in the certification of materials for aerospace, space and defence applications. The results reportedly confirm that Equispheres’ powder allowed for a 50% increase in production speeds and a 20–30% increase in a-basis mechanical performance (a design allowance specification regulated in aerospace applications).

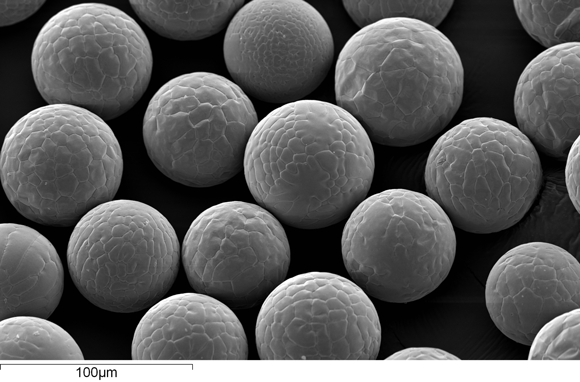

Dr Martin Conlon, Equispheres’ CTO, explained, “The unique properties of our powder, including the high sphericity, narrow particle size distribution and low surface area results in significantly increased packing density. This allows an increase of powder layer thickness by a factor of two which significantly increases build speed.”

“Most importantly, this boost to build speed does not come with a mechanical performance penalty,” he continued. “Instead, the uniform nature of our powder ensures that parts are produced with reliable and consistent mechanical properties. The minimal variance in our performance results provides design engineers the statistical confidence to produce stronger, lighter parts.”

The comprehensive series of AM coupon building and testing provided the following key technical results, contributing to overall faster production speeds and increased performance of produced parts:

- Layer thickness: 60 µm

- Mechanical performance ‘as printed’:

- Ultimate Tensile Strength (MPA): 449 ± 16

- Yield Strength (MPA): 272 ± 12

- Elongation (%): 6.4 ± 1.7

This news follows a separate study by McGill University in which Equispheres’ aluminium alloy powders were found to enable sintering following binder jet Additive Manufacturing technology, which was not previously feasible for aluminium alloy powders but has major implications for mass Additive Manufacturing.

Equispheres reported that it will now launch new equity financing as it pursues aggressive growth. Kevin Nicholds, Equispheres CEO, explained that the company now aims to get the powder onto the market on a larger scale, with a focus on long-term partnerships. “The Additive Manufacturing industry has been struggling with slow production speeds and poor-quality feedstock. We are excited that our unique powder can help resolve both critical issues,” he stated.