Eplus3D successfully tests hybrid PBF-LB manufacturing

August 16, 2022

Eplus3D, Hangzhou, China, recently undertook a project to combine its Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing technology with CNC machining in a form of hybrid manufacturing.

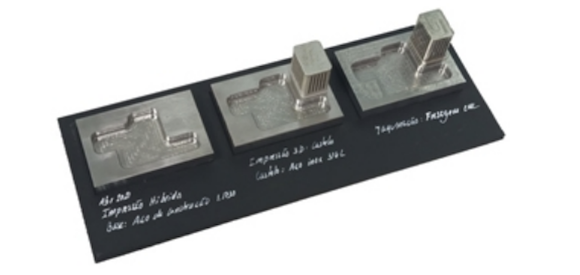

The project team began by 3D modelling the desired part and studying its possible attachment to the build platform of the EP-M150 Additive Manufacturing machine. Eplus3D selected the simple geometrical shape of a rectangular box with an inner cavity, to which an additively manufactured box would be added. An important aspect to consider was how to precisely affix the CNC machined parts onto the PBF-LB machine’s build platform. The Additive Manufacturing machine didn’t feature a straightening system as standard, but adding a fixative mechanism could have an impact on the machine’s operation.

To overcome this issue, the company opted to drill a series of holes in the build platform, allowing for parts to be affixed to it in various, precise positions in future builds, with an arrow to ensure realignment between the build platform and recoater between each build. The build platform was then secured to the machine with four screws before the CNC machined part was affixed to it, ready for Additive Manufacturing of the box into the cavity.

Eplus3D stated that its first attempt at this hybrid manufacturing process was a success, thanks to its in-depth study of the fixative process before manufacturing began. While it admits that the more typically hybridised Directed Energy Deposition (DED) Additive Manufacturing process is more versatile, it is possible to undertake hybrid manufacturing with PBF-LB Additive Manufacturing.

Some limitations noted by the company were the fact that the build planes must be perfectly horizontal in order to ensure the additively manufactured additions are welded correctly. It’s also critical to ensure that no parts of the base component extend upward into the build plane, which would hinder recoater movement.