Eplus3D introduces new EP-M1250 nine-laser metal AM machine

November 1, 2022

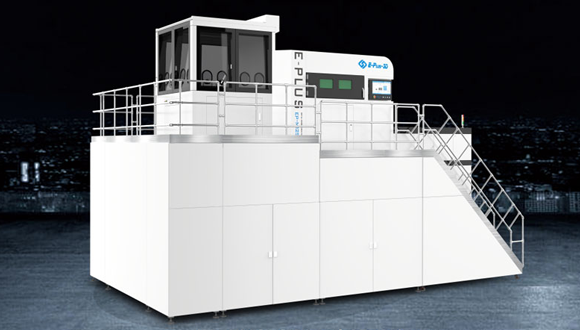

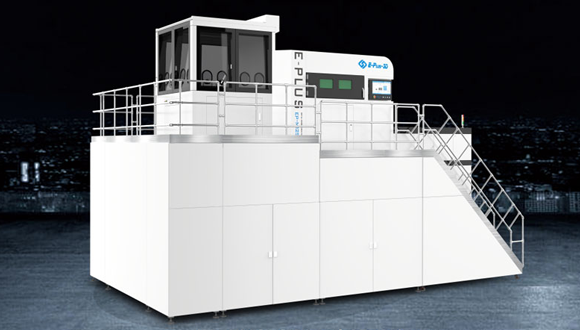

Eplus3D, headquartered in Hanzhou, China, has launched the EP-M1250, a large-format, multi-laser metal Additive Manufacturing machine. Featuring a 1258 x 1258 x 1350 mm build chamber and nine lasers, the new machine is expected to increase the development of multi-metre metal additively manufactured parts, whilst offering high productivity and reliability.

The EP-M1250 can operate with various metal powders, including titanium, aluminium and nickel-base alloys, maraging steel, stainless steel, chrome cobalt alloys and other metals. The build rate for the new machine is reported to be up to 240 cm3/h, producing parts with a density >99.9% and <5% deviation in mechanical properties.

To achieve homogeneous part properties across the build platform, the gas flow has been optimised and redesigned. The integrated process software also offers the ability to divide the build model into different sections, for which process parameters can be individually applied.

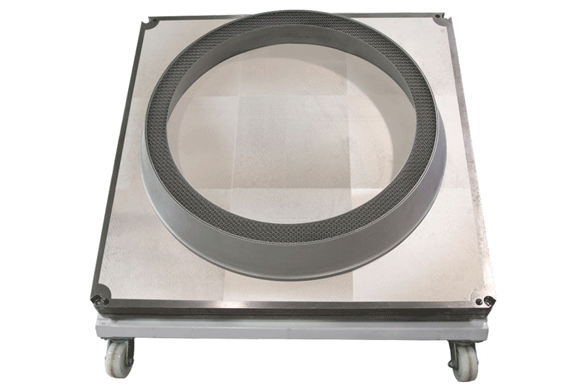

Eplus3D states that its new EP-M1250 is suitable for the direct manufacturing of large, high-precision and high-performance parts in the aerospace, aviation, automotive and machinery sectors. To highlight its capability, the nine-laser metal AM machine has been used to produce a number of additively manufactured parts for the aerospace industry. These include a stainless steel rocket engine nozzle expansion section coming in at 1050 x 160 mm (pictured above) and an In718 rocket compartment at the size of 630 x 630 x 1100 mm.

The EP-M1250 will be presented at Formnext 2022 in Frankfurt, Germany, on November 15–18. Eplus3D’s booth will be located in hall 12.0 – E22.