Eplus3D and researchers optimise hydraulic manifold valves with Additive Manufacturing

September 5, 2022

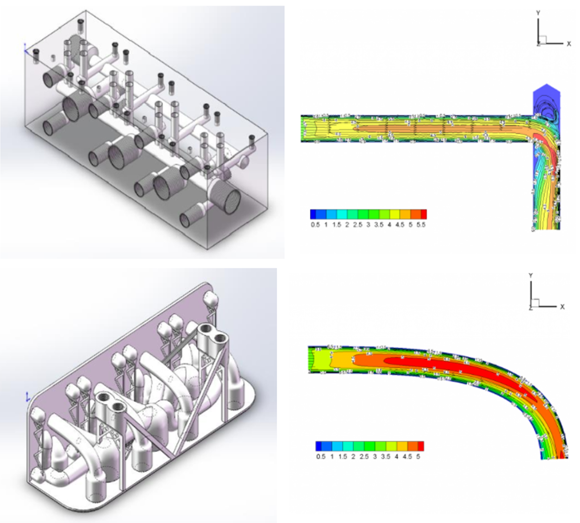

In cooperation with Eplus3D, Hangzhou, China, a team of researchers led by Dr Zhu Yi, Zhejiang University’s Metal Additive Manufacturing Laboratory, have been researching how to optimise hydraulic components using Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing. Dr Yi’s team has used the process to optimise the layout of new manifolds, redesigning and testing the internal structure in comparison to hydraulic manifolds manufactured by traditional methods.

The hydraulic manifold valve can be a complicated system, with internal passages overlapping and a convoluted inlet arrangement. With traditional manufacturing methods, holes are drilled into a solid form which then requires blocking of the unnecessary holes with screw plugs. These drilled pathways are naturally straight, with 90º turns, which can hinder fluid flow, while the overall method can also lead to leakage.

Using Additive Manufacturing, Dr Yi’s team was said to have produced a valve with its weight reduced from 1.5 kg to 0.98 kg, a weight loss of 35%, with a reported volume reduction from 535 cm3 to 116 cm3. The flow characteristics are said to have improved by changing from right-angle to smooth intersections, reducing local pressure loss when oil passes through the flow path, while the risk of leakage is reduced thanks to the lack of unnecessary channels.