EOS completes pilot phase for EOSTATE MeltPool process monitoring

September 2, 2016

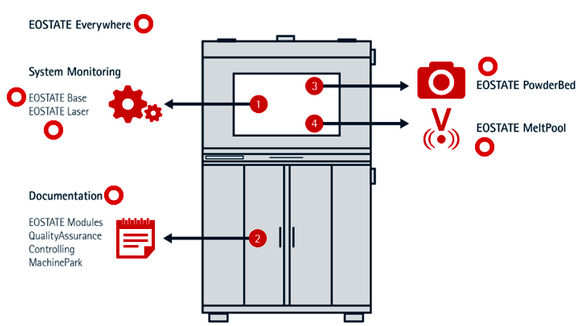

A number of process monitoring options are available for EOS systems

EOS introduced its EOSTATE MeltPool solution as an add-on to the EOS M 290 DMLS system towards the end of 2015. The system was developed to allow complete part traceability as well as an automated surveillance and analysis of the melt pool during the build process.

Following market introduction EOS exposes its products to a subsequent testing phase with a handful of pilot customers. This phase has been recently completed with EOS customer TUSAS Engine Ind. Inc. (TEI), based in Turkey.

“We consider the EOSTATE Meltpool monitoring system as an initial step for online control and part quality inspection. As such, it was part of our initial technical specifications for the DMLS process and we felt privileged to be one of the first pilot customers to test it,” stated Semih Pilatin, Technology Programs Manager at TEI.

During the DMLS build process, EOSTATE MeltPool observes the light emitted by the melt pool. Extensive hardware helps to separate the process light from the reflected laser light. The data that is obtained is further processed in the software. The software offers automatic error correction of the data that is created, as well as process visualisation and evaluation in real time. For the purpose of data analysis, the EOSTATE MeltPool Analysis Toolbox illustrates data in 2D or 3D form, including the ability to analyse discrepancies.

“We are planning to use this tool for aerospace engine parts manufacturing where tight tolerances and high performance are expected. With this tool, we can capture potential part defects online at an early stage and with minimal effort to assess the part quality,” added Pilatin.

EOS offers EOSTATE MeltPool as an extension to the EOS M 290 DMLS system for monitoring the manufacturing process. “The decisive factor for customers on the road towards series manufacturing based on AM is reproducible top-quality parts at the lowest costs per part possible. The EOSTATE MeltPool Monitoring allows to move part quality assurance from post- to in-process, as such not only supporting a better risk management, but as well reducing time and costs for quality assurance and as a consequence overall costs per part,” stated Lukas Fuchs, Application Development Consultant MeltPool for Monitoring Solutions at EOS.