Effects of shot peening on the fatigue strength of parts produced by Additive Manufacturing

March 15, 2022

With almost sixty years of experience, FerroECOBlast® Europe, based in Dolenjske Toplice, Slovenia, is one of the global leaders in the field of surface treatment technologies. The following study, performed by the company’s R&D department in collaboration with the Jožef Stefan Institute, Ljubljana, Slovenia, and Joanneum Research Centre, Graz, Austria, explores the effects of shot peening on metal parts manufactured by Additive Manufacturing.

Cold micro-forging, better known as shot peening, is a well-known surface treatment process, commonly used on machine parts in demanding industries, such as aerospace and automotive, that improves the mechanical properties of machine parts and increases their lifetime.

The question arises as to what extent the porosity and resulting micro-cracks affect the mechanical characteristics of the additively manufactured part, and what can be done to improve it. Research is being conducted into various directions: annealing and the consequential change of the metal microstructure, compression/rolling and, probably the most appropriate of all, a modern shot peening process.

Test overview

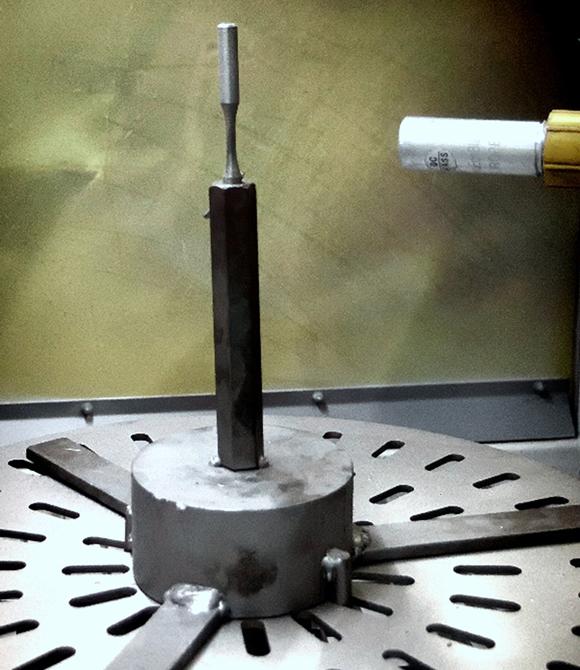

Different AM processes, and the wide range of complex parts and prototype pieces that are produced, make it difficult to select a typical machine part as a test subject. Therefore, the team chose a common test piece design, often used to perform fatigue strength tests in laboratories, for this project. The test pieces were manufactured using Laser Beam Powder Bed Fusion (PBF-LB) from three frequently used metal alloys:

- Aluminum alloy AlSi10Mg

- Maraging steel MS1 (DIN 1.2709)

- Titanium alloy Ti6Al4V

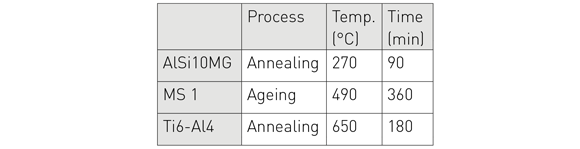

Heat treatment

The test pieces were first cleaned of residual dust and oxides before an annealing or aging heat treatment process was undertaken, as shown in Table 1.

Mechanical treatment

To ensure dimensional accuracy of the test pieces, mechanical post-processing, namely grinding, was required.

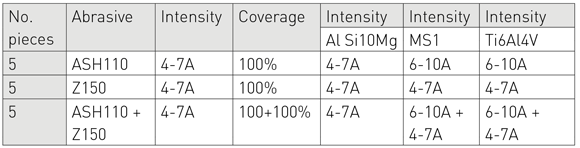

Shot peening

The final process before testing was shot peening. The selected parameters were empirically determined according to the most common parameters in practice for each particular type of conventional base material. To determine the most appropriate method, three shot peening methods with different types of shot and different intensities were selected for each tested material: Steel shot ASH110, ceramic shot Z150 and a combination of both ASH110 and Z150 for double peening (Table 2).

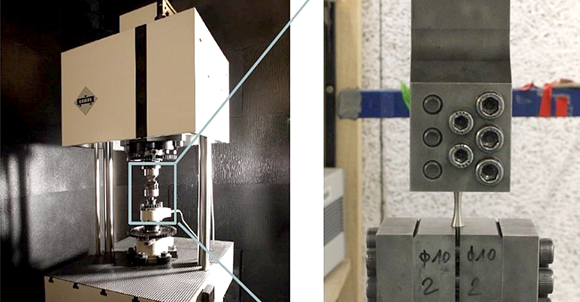

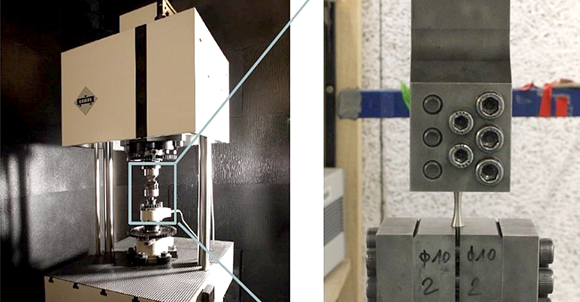

Fatigue strength testing

Tests for fatigue strength were first performed on test pieces that had not been treated with shot peening. The goal was to determine the load required to reach the breaking point of the test piece in 105 cycles and at a frequency of approximately 70 Hz. After determining the parameters, the team tested five further reference pieces not treated with shot peening, and five test pieces of each material and each type of shoot peening, resulting in a total of sixty tests.

Results of fatigue strength testing

Shot peening was shown to have a positive effect on the lasting dynamic strength of the tested pieces. A reference piece, not treated with shot peening, reached breaking point in an average of 105 cycles, while pieces treated with shot peening survived an average of 5 × 105, and up to 2 × 106 cycles. Tests show that the number of cycles required for failure depended on the shot peening parameters, as well as on the base material of the tested piece.

Metallurgical analysis

The purpose of the metallurgical analysis was to check the effect of shot peening on the base material of the tested samples, the result of which is best reflected in the microhardness. Measurements were performed on the same kind of samples tested for sustained dynamic strength.

Summary

The results of the research confirmed a significant positive effect of shot peening on the fatigue strength of parts produced by AM, regardless of the base material.

The greatest effect was detected on the titanium alloy Ti6-Al4V, where the lifetime was extended up to twenty times. It could have been even higher, but testing was stopped at 2 × 106 cycles. Samples made of MS1 steel showed a lifetime extension of approximately fifteen times, and samples made of AlSi10Mg, where the improvement was up to around eight-ten times.

The results show the best outcome is obtained with shot peening using steel shot S110, followed by double peening with steel and ceramic shot S110 + Z150. Results for pieces made of AlSi10Mg presented the largest deviation, followed by the steel samples, while with Ti6Al4V all tested methods of shot peening produced very good results.

The effect of shot peening on the microhardness of the material was not shown to be significant. Only a slight increase of microhardness was detected on the surface and up to 200-300 µm in depth. The greatest effect was detected with double peeing with S110 + Z150, which displayed an increase of the modulus of elasticity.

It was concluded that shot peening significantly improves the mechanical properties and fatigue strength of products produced with PBF-LB processes, extending part lifetime. This gives manufacturers the opportunity to further optimise part design, reducing weight and enabling faster and more cost-effective production process and significant energy savings during operation.

About FerroECOBlast

In 2020 FerroECOBlast Europe launched ADDIBLAST™ – a line of machines for advanced post-processing solutions in the Additive Manufacturing industry. The range combines three key post-processing solutions within the same product line: de-powdering (MARS), powder recovery & conditioning (STAR) and surface treatment (BAM) of additively manufactured parts.

The family of new machines follows Industry 4.0 guidelines and includes state-of-the-art automated solutions, offering more efficient depowdering of parts, recycling of excess powder, and surface treatment of AM products, regardless of the material used.