Dyndrite releases advanced raster and vector toolpathing API

October 10, 2021

Software developer Dyndrite, headquartered in Seattle, Washington, USA, has released its enhanced Raster and Vector Toolpathing API for Additive Manufacturing. These toolsets are available for license by machine OEMs developing raster-based – laser-based Directed Energy Deposition (DED), Vat Photopolymerisation (VPP) and Binder Jetting – or vector-based – Laser Beam Powder Bed Fusion (PBF-LB) – processes.

The software is also available to advanced end-customers seeking to accelerate the development and qualification of new machines, materials and geometries – without being forced to reveal IP or employ large, advanced software development teams.

“Generating toolpaths, or instructing a machine on exactly how to build your part, is critical to that part’s ultimate success, especially as the types of parts, materials, and machine capabilities advance,” stated Harshil Goel, CEO. “Machine makers and their customers require more sophisticated tools to be able to consistently deliver quality parts, especially, for example, heat exchangers, turbines, and other difficult-to-print geometries, at faster speed. The innovations being delivered by Dyndrite far surpass the capabilities of even the most advanced OEM-developed software offered today, and is only the beginning of a much requested and long overdue industry shakeup.”

The more an AM machine ‘understands’ what it’s manufacturing, the more likely it is that it will manufacture it correctly. Today, layer-by-layer interrogation strategies enable machines to see up a few layers and down a few layers, providing a ‘2.5D’ look into a 3D part. Unfortunately, this method can miss certain feature cases, leading to manufacturing failures or requiring workarounds.

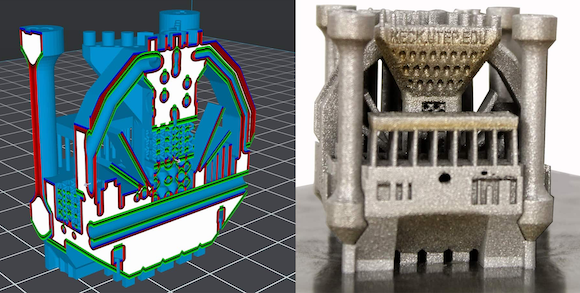

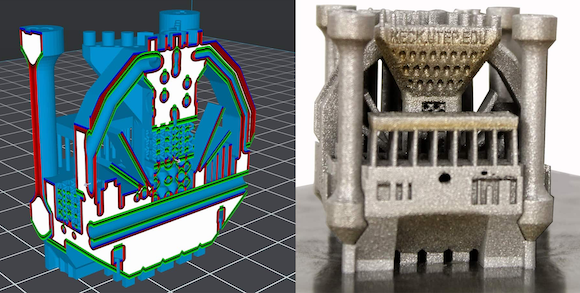

Dyndrite’s new 3D Volumetric Part Segmentation capability is said to surpass existing layer-by-layer-based boolean toolpathing methodologies by utilising its GPU-based voxel engine to enable true 3D geometric queries into any part. Further, the 3D fields are thresholded and booleaned to enable the assignment of different parameters within a single model. This zoning process enables one to develop robust build strategies that match the geometry being additively manufactured, for example resolving large and small features at the resolution of the machine, assigning high-throughput strategies for thicker sections, or implementing machine-based support strategies without having to split CAD models into discrete components.

The Dyndrite Toolpathing API enables a new class of part families by aiding the development of new materials, machines, and bespoke toolpath recipes.

Dyndrite True 3D Segmentation enables:

- Volumetric 3D assignment of parameters on each segment based on a number of variables, including distance from upward or downward faces, nearest surface, etc., while avoiding inefficient ‘2.5D’ up-skin/down-skin calculations

- Generation of ‘feature-aware’ machine tiles

- Determination of finely-graded process parameters via geometry

- Accurate calculation of upskin, downskin, orifice, and fine vertical features

- Compensation for other physical differences in a machine, such as laser angle-of-incidence

- Creation of an unlimited number of thresholds, using the API, to deliver accurate parameters to each condition in the build

- Correct parameter creation for extremely challenging geometries such as thin walls, vertical features and overhangs

Steve Walton, Head of Product, stated, “True volumetric analysis enables us to identify features that cannot be found using 2.5D analysis of layer data. It also allows us to develop more sophisticated toolpath strategies in the vicinity of fine features that are generated using any method: CAD Geometry, Mesh data from 3D Scanning, or Implicit Geometry. This goes far beyond layer booleans used to determine upskin and downskin. Now we can use 3D fields to assign parameters throughout the build.”

Dyndrite’s Toolpathing API enables more detailed assignment of parameters throughout the entire workflow, including offsetting outer contours and zones; process parameter and machine constraint assignments; machine tiling; process tiling; merging, sorting, and filtering; and micro hatching.

“Users don’t want black box solutions. Lack of transparency and democratisation is holding the additive industry back, and it is Dyndrite’s goal to shake things up by bringing advanced toolpath development and mathematics right to the users’ fingertips,’’ Goel added. “The users of Additive Manufacturing devices are often much more sophisticated than the machine vendors give them credit for and the ‘secrets’ are preventing adoption, success, qualification for new applications. This knowledge should not be locked away by existing large or newer machine vendors.”