Digital Metal launches D2 tool steel alloy for Binder Jetting

December 8, 2020

Digital Metal, part of Sweden’s Höganäs Group, has expanded its range of materials for metal binder jet Additive Manufacturing with the launch of DM D2™, a tool steel alloy that provides effective wear resistance and toughness. The company states that it is suitable for a wide range of applications, but most specifically for cutting and deformation tools.

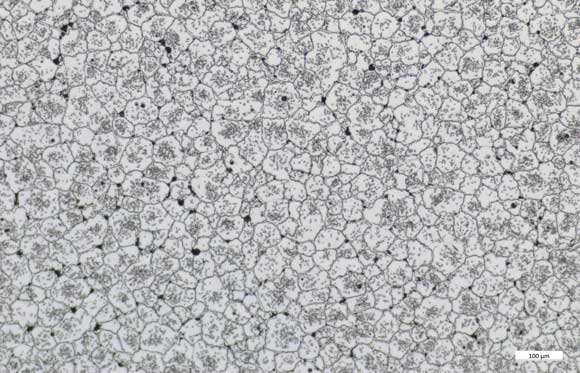

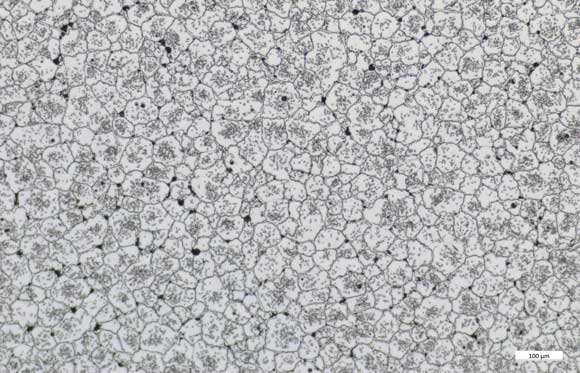

Toolmakers often choose D2 because of its hardness, meaning it is appropriate for tasks such as stamping and forming other metals without losing its shape. Digital Metal explains that DM D2 is a versatile, high-carbon, high-chromium tool steel alloy that can be heat treated to high hardness and compressive strength. Due to its high wear resistance, it is suited to cold work applications that require sharp edges and abrasion resistance.

“We have been receiving more and more requests for a D2 tool steel suitable for use with our printers,” stated Christian Lönne, CEO at Digital Metal. “We have designed the DM D2 to deliver excellent surface finish, flexibility, as well as strength and hardness. This alloy is very stable during heat treatments, which allows for tailoring of the final material properties through various heat treatments after sintering.”