Development of $1000 Wire Arc AM machine

January 7, 2022

Engineering researchers from California State University, Los Angeles, USA, and Eskisehir Osmangazi University, Turkey, have published ‘Development of a Low-Cost Wire Arc Additive Manufacturing System’ in the Journal of Manufacturing and Materials Processing. The paper outlines the joint development of a Wire Arc AM (WAAM) machine – intended for the development and repair of high-value components – which can be built for around $1,000.

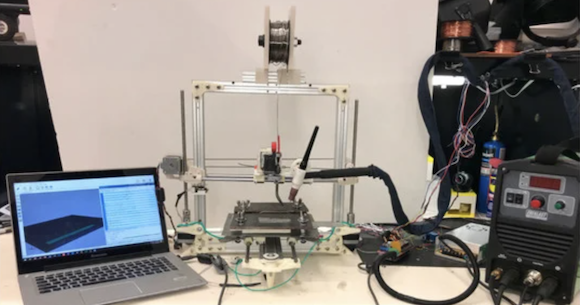

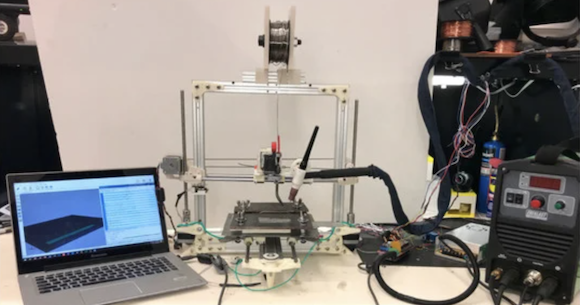

Traditionally, the WAAM machine, a type of Directed Energy Deposition (DED) technology, utilises complex robotic arms and expensive CNC equipment to precisely position components. This paper aimed to demonstrate that a standard gantry system, typical of Fused Deposition Modelling (FDM) machines, can be utilised to manufacture an affordable option for metal AM.

The gantry system used in these experiments was inspired by an open-source design known as Bukobot, which features z-axis vertical square frame and a perpendicular x-y axis carriage. All process controls and programming of the system (i.e., host, firmware, slicer, and modelling software) were based on an open-source architecture.

Plain carbon steel AISI 1030 and Inconel 718 wires were selected to test the systems, pushed through a melt pool into a custom-made automated wire feeder. Preliminary testing consisted of selecting ideal parameters for AlSl 1030, with settings based on wire-feed speed, torch travel speed and electrical current. After single-pass tests for each parameter set and material, multi-pass tests were performed.

While some limitations were noted (e.g., limited environmental protection of the metal build from the atmosphere), many are addressable by customisation (using an enclosed inert gas-filled chamber around the build). With proper parameter selection, the paper states that the system can process a variety of metals – such as titanium and alloys, nickel- and cobalt-based superalloys, and low-alloy steels – with less effort and at lower cost than Powder Bed Fusion (PBF) systems.

‘Development of a Low-Cost Wire Arc Additive Manufacturing System’ was written by Miguel Navarro, Amer Matar, and Mohsen Eshraghi of California State University and Seyid Fehmi Diltemiz of Eskisehir Osmangazi University. It is available to read in full here.