Desktop Metal qualifies nickel alloy IN625 for its Production System

October 15, 2021

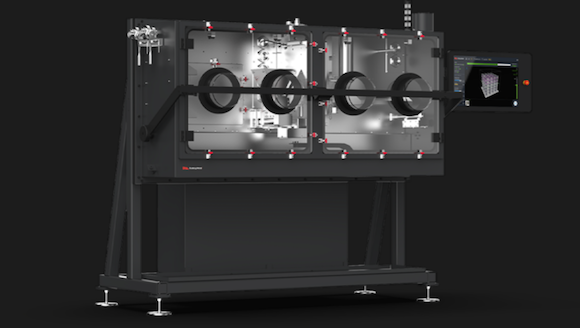

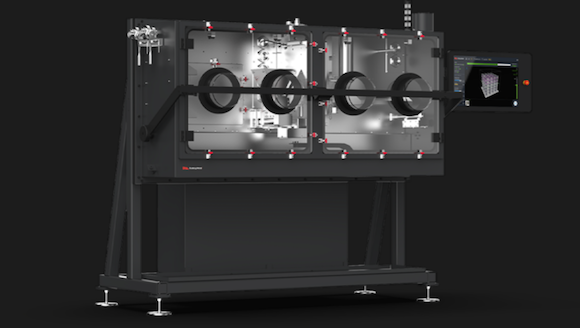

Desktop Metal, Inc., Boston, Massachusetts, USA, has announced the qualification of nickel alloy IN625 for the Production SystemTM platform, which makes use of its patent-pending Single Pass JettingTM Binder Jetting (BJT) technology designed to achieve fast build speeds.

A nickel-chromium superalloy, IN625 is characterised by its high strength, resistance to corrosion and oxidation, excellent weldability, and ability to withstand extreme, elevated temperatures for parts under load. As such, IN625 is a critical material in high temperature aerospace applications, while its corrosion resistance under a range of temperatures and pressures makes it well suited to applications across marine, power generation, and chemical processing.

“As Desktop Metal continues to drive our internal R&D efforts to qualify more materials for the Production System platform, we are excited to offer customers an all-inclusive Binder Jetting solution to print fully characterised IN625 with excellent properties,” said Jonah Myerberg, co-founder and CTO. “We anticipate continuing the rapid expansion of our materials portfolio in the coming months as we look to accelerate the deployment of our AM 2.0 solutions to produce end-use metal parts at scale across a growing array of industries and applications.”

Jason Harjo, Director, Mechanical & Electrical Design (Americas), Koch Engineered Solutions, added, “As a transformative combustion equipment company, we are very excited about the release of IN625 for its high temperature and corrosion-resistant properties in flaring and sulfur incineration applications. This will give us much more flexibility in innovative, Additive Manufacturing designs for some of our most difficult applications.”

Desktop Metal’s materials science team has qualified and fully characterised IN625 manufactured on its Production System technology in accordance with ASTM testing requirements. IN625 parts additively manufactured on the Production System platform were reported to eliminate the use of tooling and minimise material waste at a significantly decreased production time and part cost compared to conventional manufacturing methods.

Examples of key use cases include:

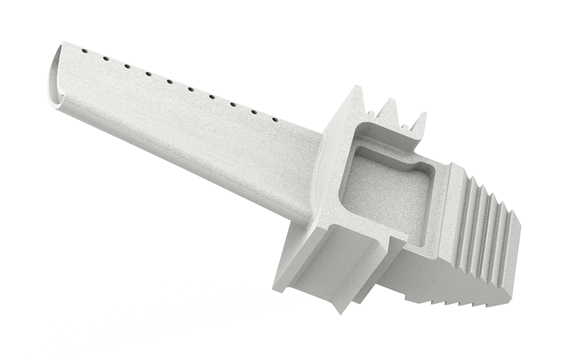

- Hydraulic Spool: These are a key oil & gas application that assist in adjusting the flow rates of control valves; IN625 is an essential material to ensure longevity and withstand highly corrosive environments in oil & gas. When produced using traditional manufacturing methods, the spool must typically be assembled from several machined components. With the Production System, each hydraulic spool can be jetted as a single part rather than multiple components, enabling a reduction in assembly labor costs.

- Turbine Blade: Critical components used in gas or steam turbines in the aerospace industry. These blades are some of the most challenging components to mass produce due to complex geometries, including organic curves that optimise aerodynamics, and complex cooling channels that ensure the blades maintain an optimal temperature. The Production System enables the Additive Manufacturing of such geometries, which would otherwise be challenging to produce using traditional manufacturing methods and require advanced casting and machining techniques. IN625 is an ideal material for these blades because of its high tensile, creep, and rupture strength, fatigue and thermal-fatigue strength, and corrosion resistance.

- Internal Combustion Block: These are used in aircraft engines and often feature extremely complex geometries that are outside the ability of most machine shops and require multiple machining setups and advanced CAM programming. With the Production System, this part can be additively manufactured to near-net shape without the need for any tooling, and the critical internal dimensions can be touched up in just a few hours with minimal machining setups needed. In addition, because this part experiences extremely high forces and temperatures during the combustion stage, IN625 is an ideal material choice for its incredible material properties in these environments.