Desktop Metal acquires hydraulic systems maker Aidro

September 9, 2021

Desktop Metal, Inc., Boston, Massachusetts, USA, reports that it has acquired Aidro, headquartered in Taino, Italy, a pioneer in the volume production of next-generation hydraulic and fluid power systems through metal Additive Manufacturing across a wide range of industries, including oil and gas, agricultural equipment, aerospace, and mobile and industrial machinery and more.

“This acquisition advances Desktop Metal’s strategy to support our major OEM customers with proprietary design and application know-how as well as through a combination of best-in-class AM products and high-value parts production across killer applications for AM 2.0,” stated Ric Fulop, founder and CEO of Desktop Metal. “Aidro brings a talented team with decades of experience in hydraulics and fluid power systems and a passion for leveraging AM to deliver performance advantages to their customers. We’re excited about the acquisition and look forward to advancing AM 2.0 for high-volume production of hydraulics, valves, fluid power systems, and many more end-use parts in development with Aidro.”

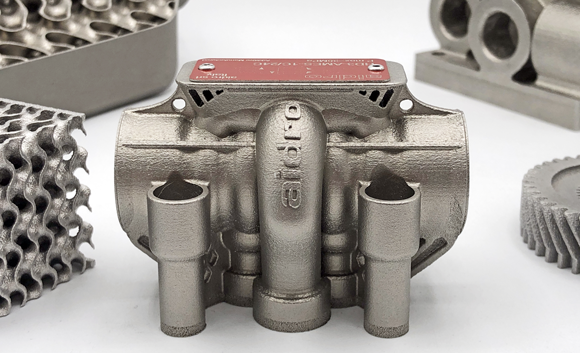

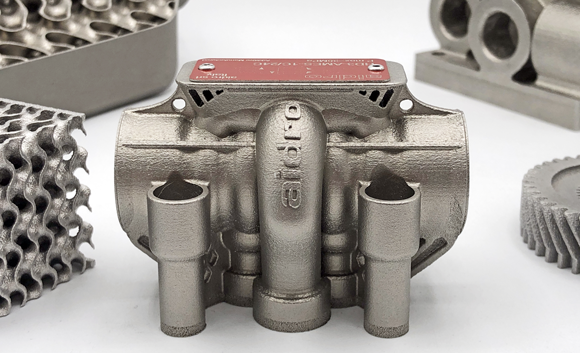

Founded in 1982, Aidro has almost forty years of experience in the design and production of valves, manifolds, and various hydraulic components and fluid power systems. It offers expertise in design for AM, including finite element analysis simulation and topology optimisation techniques.

Aidro engineers leverage these technical capabilities to redesign traditional hydraulic components for AM production using complex geometries to reduce weight, save space, and consolidate multiple components into one, eliminating assembly and welding requirements. Hydraulic components produced by Aidro using AM improve performance versus conventional manufacturing by optimising flow channel placement and geometry to increase flow capacity and decrease pressure drops.

In order to offer customers innovative and custom solutions, Aidro has invested in AM facilities and processes alongside its conventional manufacturing capabilities. The company’s dedicated AM department features metal AM machines, 3D scanning technologies, and ISO9001 and AS/EN9100 certifications, all leveraged to deliver high-performance products to customers, including industry-leading original equipment manufacturers (OEMs), while reducing production lead times for volume quantities of end-use components, spare parts, or on-demand rapid prototypes.

Valeria Tirelli, co-CEO and president of Aidro, commented, “Additive Manufacturing offers benefits unmatched by conventional manufacturing, and once Aidro realised the advantages of leveraging AM, we quickly allocated resources to develop expertise and take advantage of the opportunity. This partnership is the next step in our AM evolution, and now, with access to Desktop Metal’s scale and industry-leading AM 2.0 technology portfolio, including its volume production-focused metal Binder Jetting solutions, we’re thrilled at the growth potential for Aidro.”

Tommaso Tirelli, co-CEO and VP Business Development of Aidro, said, “We are thrilled to join forces with Desktop Metal. This partnership will enable us to continue investing in the expansion of AM for next-generation hydraulic solutions to disrupt massive industries such as oil & gas and aerospace.”

Alberto Tacconelli, GM of Aidro, added, “With the collaboration and support of Desktop Metal, we will be able to take our AM capabilities in hydraulics to the next level We are ready to embrace AM to develop innovative products for our customers, leveraging mass production technologies to achieve affordable part costs and high-performance designs that overcome the limitations of conventional manufacturing.”