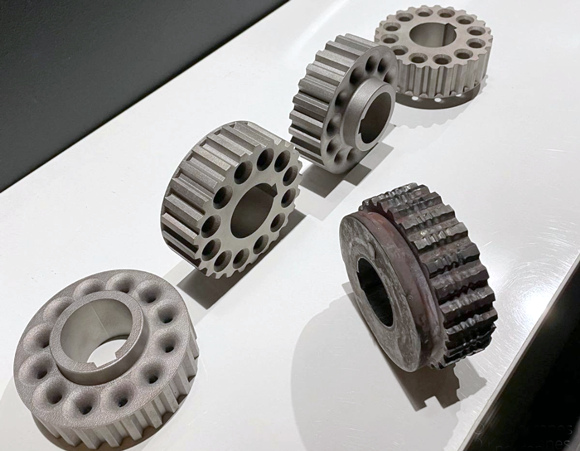

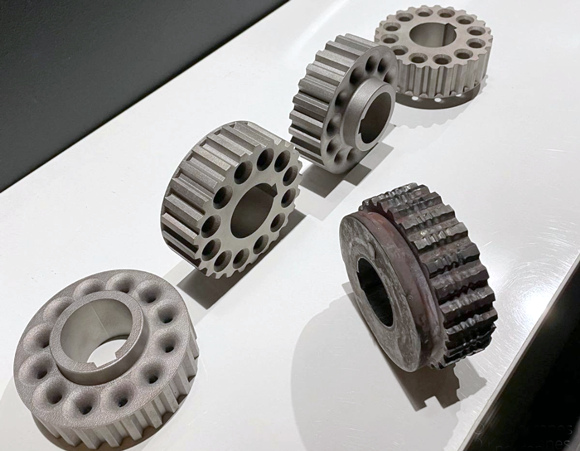

Delva additively manufactures gear replacement for crane brake assembly

June 28, 2022

Finnish crane manufacturer Konecranes recently turned to Additive Manufacturing service bureau Delva, Hämeenlinna, Finland, as it sought a solution on how best to replace a worn gear out of a crane conveyor reel’s brake assembly.

To start, Delva scanned the defective gear and used the result to reverse engineer and model the component as a digital design. In leveraging the abilities of Additive Manufacturing, the gear was lightweighted, which reduced the cost of implementation. This lightened solution will also put less load on the bearing while it is in use, enabling additional benefits to be realised over time.

In addition, the original separate rubber support mounted on the wheel could be eliminated by designing a closed gear ring, thereby preventing the brake discs from falling off. To increase wear resistance, the company selected MS1 tool steel to additively manufacture the part.

In the initial case study, Delva additively manufactured and heat treated the components. The wheel was wire cut from the build plate and the axle hole was wire cut to size. In this, the accuracy and surface quality of the additively manufactured part met all expectations.