The continuing evolution of titanium powder production at AP&C

June 14, 2017

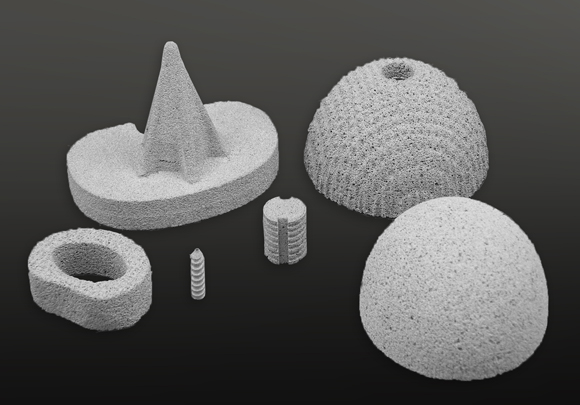

Titanium hip joint replacement parts

When it was announced earlier this year that Canada’s AP&C, a GE Additive Company, had received an order for 30 tons of plasma atomised titanium powder for a Metal Injection Moulding (MIM) application, it became clear that titanium MIM had reached the mainstream.

In an article written for Powder Injection Moulding International, Vol. 11, No. 2, AP&C explains the attraction of MIM for titanium components, outlines the company’s plasma atomisation process and presents its growing range of products specifically suited to the MIM process.

Expanding the usage of MIM to new applications requires a ramping up of the supply of titanium powders with the required tailored size distributions and consistently high quality. The plasma atomisation process used at AP&C has the ability to provide powders with precisely controlled properties – a necessary requirement for a broad range of current and potential MIM applications.

In its six-page, fully illustrated article, the company surveys the continuing evolution of the plasma atomisation process as it evolves to deliver the large quantities of high-quality fine powders required if MIM technology is to reach its full potential.

Readers can view the digital edition of PIM International Vol. 11, No. 2 free of charge via the magazine website.