CDU boosts metal Additive Manufacturing in Australia with purchase of LightSPEE3D Printer

July 20, 2017

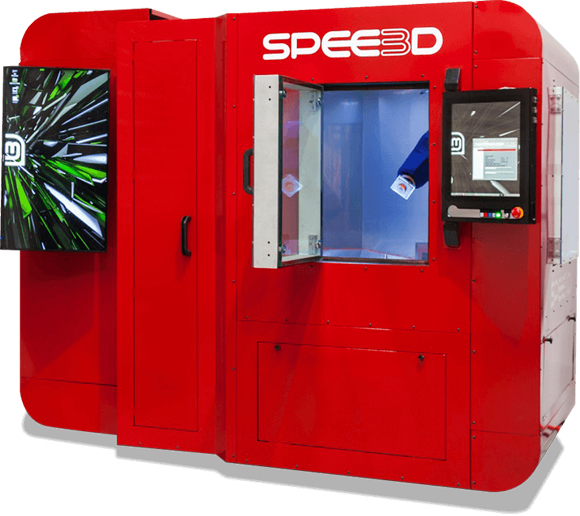

The LightSPEE3D Printer (Courtesy SPEE3D)

Charles Darwin University (CDU), Darwin, Australia, has announced that it will acquire a LightSPEE3D Printer from Darwin-based Additive Manufacturing start-up SPEE3D. The acquisition will be made possible by a grant of AUD $400,000 from Australia’s Northern Territories Government, which hopes to drive innovation in the region by boosting AM development.

The LightSPEE3D AM system, developed by SPEE3D’s Steven Camilleri, is based on cold spray technology and reportedly enables metal Additive Manufacturing at speeds of up to 1000 x faster than those allowed by existing powder bed fusion and wire based AM. SPEE3D claims that the machine has the potential to transform industrial metal Additive Manufacturing.

Michael Gunner, Chief Minister for the Northern Territory, stated that the printer would form the centrepiece of a new industrial research hub to be based at CDU’s Casuarina campus. This hub, the Minister stated, will pave the way for the creation of jobs into the future for Territorians as well as generating new economic opportunities in the region.

“We want to partner with local enterprises to drive innovation here in the Territory. By diversifying the economy through innovation we are opening the door to new economic opportunities for Territorians – both now and into the future,” he commented.

Together with CDU, SPEE3D has formed the Advanced Manufacturing Alliance (AMA) based at Casuarina campus. CDU’s Professor Maddocks stated the AMA also would work to develop applications for the use of the new technology in remote areas, with the aim of improving supply chains and lowering operating costs.