CERN’s Engineering department AM Workshop deploys Solukon depowdering unit

December 11, 2018

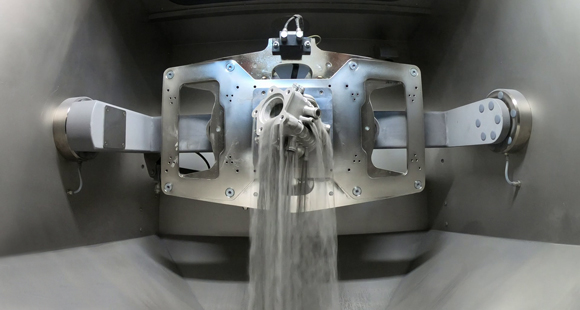

A Solukon depowdering unit tilts a part on the build plate to remove metal powder from internal channels (Courtesy Solukon Maschinebau GmbH)

The Mechanical and Materials group at the European Organization for Nuclear Research (CERN) has deployed automated depowdering units from Solukon Maschinenbau GmbH, Augsburg, Germany, for processing metal additively manufactured parts made from reactive titanium-alloys in a Laser Beam Powder Bed Fusion (LB-PBF) process.

“Powder removal is a critical phase of Additive Manufacturing,” stated Romain Gérard, an AM engineer at CERN’s Engineering department’s Additive Manufacturing Workshop who deals with ultra-high-vacuum applications. “We observed that powder residues that are subsequently sintered during heat treatment act like sponges by trapping gases and releasing them at a very low rate. The SFM-AT300 automated depowdering unit from Solukon ensures a high depowdering quality with a safe environment for titanium and niobium powder.”

“The high requirements for safety and cleaning results make CERN’s Engineering department Additive Manufacturing Workshop an exemplary customer for Solukon,” commented Andreas Hartmann, CEO and Technical Director at Solukon. “The combination of the reactivity of the used titanium powder and the complex internal structures of the parts make it perfectly suitable for our systems.” Dominik Schmid, CEO, added, “Through programmable rotation of the part and the build plate around one or two axes, non-fused build material is removed from complex voids and support structures.”