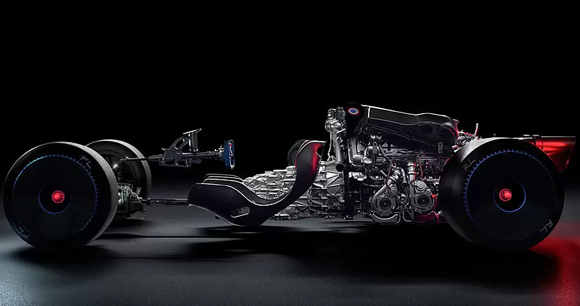

Bugatti highlights metal Additive Manufacturing in its Bolide hyper-car concept

January 26, 2021

Luxury French carmaker Bugatti, owned by VW group, has announced further use of metal Additive Manufacturing in the development of its state-of-the-art supercars. A number of titanium additively manufactured parts have been identified in the company’s latest concept, the Bugatti Bolide.

An additively manufactured pushrod, weighing just 100 g, is one of the components developed for the Bolide. The hollow titanium structure incorporates an internal supporting arch, giving the part the incredible strength that can transmit forces of up to 3.5 tonnes.

For the first time, the Bugatti developers varied the wall thickness of the thin-walled, hollow rods. They become thicker towards the centre and then thinner again, meaning that they are optimally adapted to localised stress. Similar to a human bone, the component also has an internal structure, which was recently registered as a patent.

The development project was led by Henrik Hoppe, a doctoral student in the New Technologies department at Bugatti, who has been working on innovative metal materials and manufacturing processes since 2017. He wrote his master’s thesis on a calculation methodology for an additively manufactured titanium brake calliper, which is 43% lighter than the already highly weight-optimised Chiron production component, and just as rigid.

Discussing the new pushrods in the Bolide, Hoppe stated, “Through the process known as selective laser melting, commonly known as 3D printing, new, hollow, ultracomplex components that are stiffened from the inside can be produced which are very lightweight and yet extremely rigid and strong.”

“We are utilising these benefits for an increasing number of components in our hyper sports cars,” explained Hoppe.

In his doctoral thesis, Hoppe is pioneering a new system owing to the cost- and time-intensivity involved with the complete cycle of the manufacturing process chain, from concept to delivery. Hoppe uses this system to identify the commercial and technological potential of functional metal AM components for automotive manufacture, and can enhance this potential with applied targeting at specific parts. Previously, these types of components were used predominantly in the aerospace sector.

Applying principles from the field of bionics to give the AM designs its bone-like structure, Bugatti is producing components featuring thin walls with a hollow interior and fine branching, giving them remarkable rigidity despite their low weight, and wall thicknesses of up to just 0.4 mm.

“We will continue to reduce the weight of our cars while increasing their innovative features in every conceivable area,” added Hoppe. “Although Bugatti demands the highest quality standards in terms of materials, manufacturing processes and components, they must be commercially viable.”

The Bugatti Bolide celebrated its world premiere in late October 2020. “As an experimental vehicle in the form of a racing car, the Bolide is no show car: it is an uncompromisingly road-ready extract of Bugatti’s complete technological expertise. Bugatti enthusiasts will also find these cutting-edge technologies in other vehicles in the future,” stated Frank Götzke, Head of New Technologies at Bugatti.

Just like the turbofans typically used in motorsport, Bugatti has found a way of including radial compressors on ultra-lightweight magnesium forged wheels. Their appearance is similar to that of a wheel rim, but they perform multiple functions: pumping the air out of the wheel housings through the brakes and drawing the warm air to the outside. In this way, the turbofans cool the brakes and minimise lift. In contrast to the well-known monomaterial solutions, the Bolide components have a hybrid structure. This consists of a central bowl made of titanium AM, with a thickness of 0.48 mm, and a 0.7 mm thick carbon plate with small inner blades, also made of carbon. Cross-pieces with a width of 0.48 mm further increase the rigidity of the central titanium bowl, which weighs just 100 g. This would not be possible with a monomaterial solution due to the fact that it is not possible to achieve the specific buckling resistance and flexural rigidity.

Highly-complex AM components are also used in hidden places. A mounting bracket for the front wing, on which the front wing can be mounted at three different heights, is made from titanium by Bugatti. With a hollow interior and a wall thickness of 0.7 mm, the mounting bracket can withstand an aerodynamic downforce of up to 800 kg – with a weight of just 600 g.

The downforce of the rear wing, which can reach up to 1.8 tonnes at 320 km/h, is introduced via the Bolide’s central carbon fin into the upper structural matrix, which forms the upper termination of the high-strength stainless steel rear frame. Inside this central fin there is a laminated titanium AM component for connecting the fin to the wing, for which the angle can be adjusted by means of a coupling rod. Despite its rigidity, it weighs just 325 g.

The engineers also use titanium AM for the bracket mounting the steering column, which features an integrated dashboard support, the support collar for the steering column throughfeed, and the two air vents in the vehicle interior. All components are designed as lightweight hollow structures, with a uniform wall thickness of 0.5 mm.

The Bolide’s suspension and steering system incorporate further AM components. In the case of the horizontal spring damper elements on the front axle, the vertical contact forces are transmitted by means of a linkage located directly beside the swivel bearings on the lower wishbones via pushrods and rockers. The brackets that control the rockers have a wall thickness of just 0.4 mm and weigh 95 g each. The rockers weigh just under 195 g each.

Since air flows completely through the Bolide’s front axle, its kinematic components – both the titanium AM components and the high-strength stainless steel wishbones – are extremely lightweight, rigid and aerodynamically optimised. The tensile strength of this and all other AM elements is 1,250 N/mm2. “Using a special heat treatment process developed in-house, we achieve this high tensile strength with a simultaneously high fracture strain of at least 19%,” explained Götzke.

In the tailpipe trim cover, a hybrid component made of titanium AM and ceramic, Bugatti reduced the weight by around half compared to the already weight-optimised titanium tailpipe trim covers well known from series production. The component, which measures more than 280 mm in length and has a consistent wall thickness of just 0.5 mm, weighs less than 750 g. Since ceramic material is a significantly less effective heat conductor than titanium, Bugatti introduced special ceramic elements that are built into the titanium housing and centre the cover with respect to the carbon outer skin, so that the outer skin is not damaged even at high exhaust gas temperatures. This thermal shield is also supported by a built-in Venturi nozzle: when hot exhaust gas enters the tailpipe trim cover, fresh air is drawn in, thereby creating a jacket of cool air around the hot exhaust gas flow. In its entirety, this is an invention for which Bugatti has also submitted a patent application.

“It is the Bolide’s many technological highlights that make it so special. But these can also be transferred to production vehicles,” Götzke added. “This is what we are continuing to develop and work on, because Bugatti has set itself apart with its impressive innovations for over 110 years – and will continue to do so in the future.”