BMW reports successful integration of automated AM car parts production line

May 27, 2022

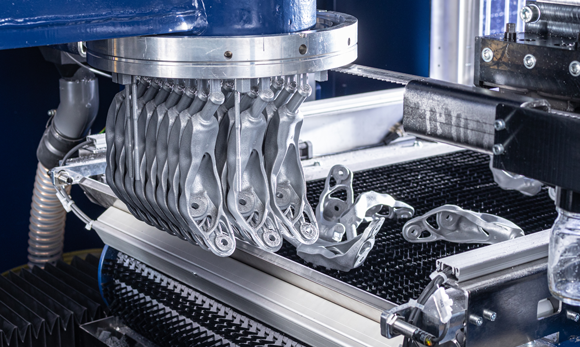

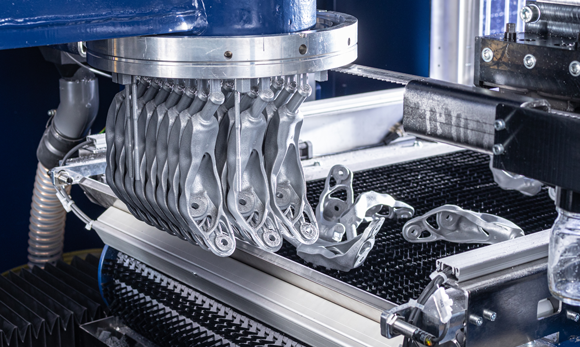

BMW has reported success in its aim to industrialise and digitalise the Additive Manufacturing of components for use in automotive series production. Together with the twelve members of the Industrialisation and Digitalisation of Additive Manufacturing (IDAM) consortium, which was launched in 2019, a digitally connected, fully automated Additive Manufacturing line, specifically for series production of automotive components, has been established at the BMW Group Additive Manufacturing Campus in Oberschleissheim, Germany, with a further production line located at GKN Powder Metallurgy’s facility in Bonn.

BMW states that approximately 50,000 components per year can now be manufactured cost-effectively in series part production, as well as more than 10,000 custom or new parts, using its Laser Beam Powder Bed Fusion (PBF-LB) technology. By using this Additive Manufacturing process, the group explains that certain tools are no longer required and new design possibilities can be realised, greatly increasing its manufacturing flexibility.

A fully automated driverless transport systems (FTS), which began as a concept outlined in 2019, is used to carry mobile AM build chambers between modules in the IDAM production lines. Further automation sees processed metal powder delivered to workstations for preparation, and post-processing of the additively manufactured components is conducted automatically at specially designed stations.

Quality assurance of the finished parts takes place in-line, during the AM process, using sensors. This includes checking emissions from the molten pool with a CMOS camera and pyrometer. AI algorithms are used to correlate the data collected with actual component quality. The result is that process deviations can be identified during production and component quality evaluated.

The successful implementation of the IDAM project, which was funded by the German Federal Ministry of Education and Research (BMBF) and led by the BMW Group, was said to be due to the combined expertise of all project partners. “From the very first day of the project, you could feel the team spirit among the partners,” stated Felix Haeckel, consortium leader and BMW Group project manager.

“Learning from one another, developing innovative solutions together and making the best use of each partner’s individual strengths – those were key to successful industrialisation and digitalisation of Additive Manufacturing,” concluded Haeckel.