Blue Power and Amazemet develop compact ultrasonic atomiser

November 12, 2020

Blue Power Casting Systems GmbH, Walzbachtal, Germany, in cooperation with Amazemet Sp. z o. o., a Warsaw University of Technology spin-off company, have developed a compact ultrasonic atomisation unit for R&D purposes and small powder batch production.

With Blue Power’s twenty-five years of experience in induction melting technology and Amazemet’s know-how in ultra-high temperature ultrasonic technology and materials science in Additive Manufacturing, the two companies explain that they decided to combine their expertise to develop an innovative unit with unique functionalities and profitability.

Dr Fischer-Bühner, Head of R&D at Blue Power, explains that the atomiser unit enables users to produce small batches of high quality, spherical powder for the same target application as gas atomised powder at an affordable price and without complex infrastructure.

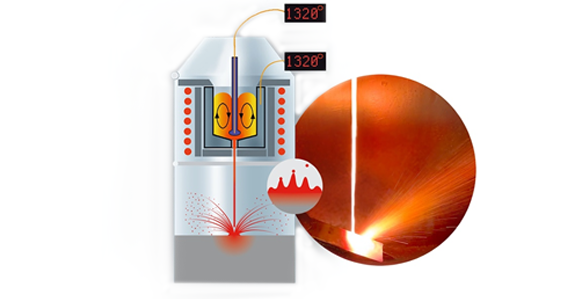

The ultrasonic atomiser solution features a crucible-based induction heating system which allows the melting temperature to be precisely controlled, therewith preventing the loss of alloy ingredients such as zinc and chromium through evaporation. The melting can either take place under vacuum or in a controllable atmosphere. The powerful medium-frequency induction generator produces excellent stirring/mixing effect, improving the quality of the alloying.

“A crucible-based induction heating system has many economic benefits over plasma-assisted ultrasonic atomisation,” commented Mateusz Ostrysz, co-founder of Amazemet.

For example, the loss of alloy ingredients through evaporation is prevented without the need for any sophisticated and expensive filtration systems, state the companies. The system is not restricted to just pre-alloyed wire and bar; the feedstock can be any shape. This means that users can avoid the time and effort needed to produce complex and expensive wire, no longer needing the associated infrastructure such as continuous casting machines and drawing benches.

Very small batch sizes, of around 100 g or less, are reported to be both technically and financially viable, while larger production capacity of up to several kg (bronze) per hour is possible. An increased powder yield is made possible due to operating at a higher frequency (up to 80 kHz). For example, bronze particle sizes in the range of d50= 40 to 60 µm can be easily achieved, with further improvements on the horizon.

The ultrasonic process is said to be as flexible as users require in terms of both inputs and outputs. The plant can reportedly handle almost any non-ferrous metal in any shape with a melting temperature less than 1300°C, with the company also developing an 1800°C version. No calibration is needed; pre-installed programs take care of the basic materials and alloys. The machine can also be used for granulating and ingot casting.