BLT and Wego Ortho partner to bolster Additive Manufacturing for orthopaedic implants

May 11, 2023

Bright Laser Technologies (BLT), Xi’an, China, and Wego Ortho, a subsidiary of Shandong Weigao Group Medical Polymer Co Ltd, have recently highlighted the strength of their collaboration in driving the adoption of Additive Manufacturing within the medical market. The partnership was built upon Wego Ortho’s purchase of a BLT-S310 metal Laser Beam Powder Bed Fusion (PBF-LB) AM machine from BLT in 2020.

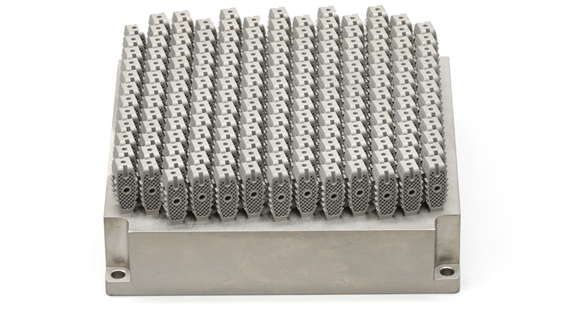

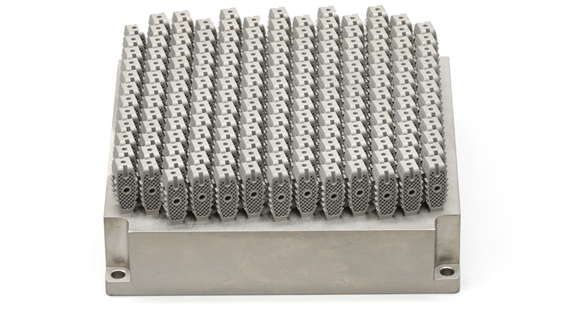

One area in which metal Additive Manufacturing has made a significant impact within the medical industry is in the production of spinal cages, which are used to treat conditions such as degenerative disc disease, spondylolisthesis, and other issues that affect the spine.

Traditionally, these cages are made to standard sizes, meaning patients may not have had a perfect fitting spinal cage. Through the use of Additive Manufacturing, spinal cages can now be made bespoke to each patient. The spinal fusion cage developed by Wego Ortho is a complex, high-precision porous structure with many overhanging features. These parts have strict requirements regarding process parameters and require the addition of support structures during forming.

To achieve these requirements, BLT and Wego Ortho collaborated and successfully developed a full set of solutions from product design and material selection, to production and final testing. BLT also provided specialised training to the staff of Wego Ortho to help them master the operation of the machine, and assisted the company in successfully additively manufacturing products with the required surface quality, mechanical properties, and dimensional accuracy to reach medical grade.

The company’s BLT-S310 features a 250 x 250 x 400 mm build area with dual lasers, and can achieve a maximum build speed of 50 cm3/h. The machine can additively manufacture parts in copper, titanium alloys, aluminium alloys, super alloys, and other materials. A surface roughness of Ra6.3 being achievable and thus meeting the requirements of the aerospace, medical, automotive, and electronics sectors, amongst others.

It is expected the partnership will continue to conduct in-depth exploration and research in the direction of metal Additive Manufacturing of titanium alloy, tantalum, cobalt chromium molybdenum, magnesium alloy and other medical-grade materials, and promote research into the application of Additive Manufacturing to other relevant products and fields.

In the future, BLT said it hopes to partner with more customers in the medical field to further the adoption of Additive Manufacturing in the market.

Download Metal AM magazine