Barnes Group Advisors and Expanse Microtechnologies offer course on CT for Inspection in Additive Manufacturing

August 23, 2018

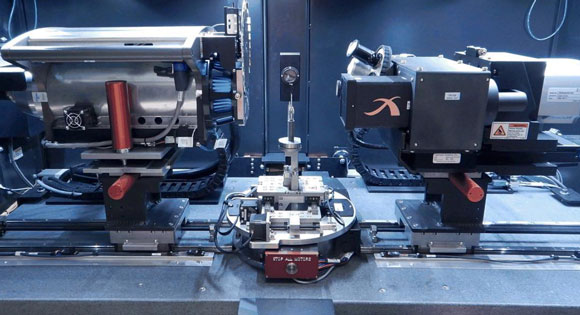

View of Zeiss Versa 520, property of the Multi-Scale Additive Manufacturing Lab (image credit: Expanse Microtechnologies)

Additive Manufacturing consultancy The Barnes Group Advisors (TBGA), Pittsburgh, Pennsylvania, USA, and provider of customised 3D xray imaging Expanse Microtechnologies Inc., Toronto, Canada, have announced a joint partnership focused on the analysis and inspection of additively manufactured parts. The two companies will offer a new co-developed training course, CT for Inspection in Additive Manufacturing.

In addition to the fundamentals of micro-CT, trainees will be given an introduction to the depth of information that can be gathered using micro-CT with respect to key Additive Manufacturing concerns. Trainees will review a number of AM case studies, looking at real manufacturing defects and how to properly assess them. The goal of the course is said to be to ‘demystify’ the technology, and it will offer insight not only into the capabilities of the technology but also some of the trade-offs and limitations which must be understood.

The training course will begins with an introduction to CT and CT fundamentals, followed by sections on classifying CT applications, understanding the technology trade-offs, designing for CT, and close with a best practices session on the purchase of CT equipment. John E Barnes, Managing Director, TBGA, stated, “This training will bring advanced CT technologies to the hands of engineers, and will help get the most useful inspection data in the shortest amount of time.”

“Everyone in the industry should be exposed to the capabilities and limitations of this technology,” added James Hinebaugh, President, Expanse Microtechnologies. “Micro-CT inspection will play a critical role in the exponential expansion of Additive Manufacturing applications, and it will be those that master quality and inspection that will be the forerunners of that expansion.”

Alison Wyrick Mendoza, Additive Manufacturing Training & Services Leader, TBGA, added, “Several of our TBGA training customers expressed interest in this specialised topic. We feel this is also the perfect opportunity to leverage our relationship with Expanse, one of our Partner AM™ members.”

The course length will range from 1–3 hours depending on the depth and breadth of the topics requested. It is currently delivered via webinar or in-person workshop.