BAE Systems Air to employ Simufact Additive for metal Additive Manufacturing

January 31, 2019

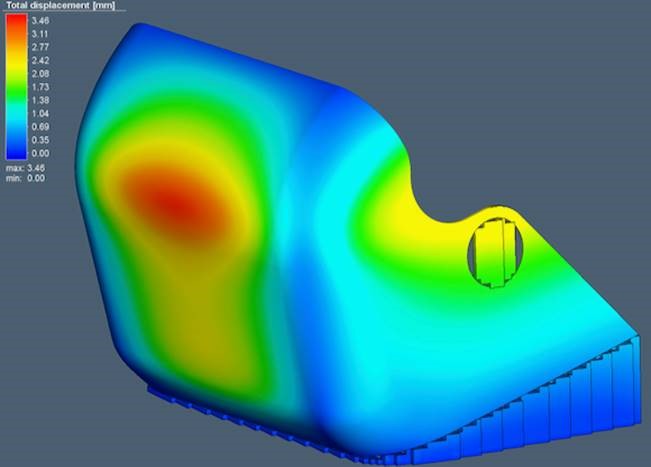

A metal additively manufactured BAE Systems Air part as represented in Simufact Additive (Courtesy Simufact)

The Air division of BAE Systems, headquartered in Farnborough, UK, has selected Simufact Additive software, developed by Simufact, Hamburg, Germany, for the simulation of metal additively manufactured components. In 2015, BAE Systems opened a new Product and Process Development Centre, where it has since conducted trials of the market leading packages for the simulation of metal AM processes.

At the end of this trial phase, the company concluded that Simufact Additive software can deliver good results, and stated that its has gained great confidence from the trials carried out. In addition, BAE Systems is already using other MSC Software products in its facilities, such as MSC Nastran, Patran and MSC Apex. By choosing Simufact Additive, BAE ensures that its products come from a single source, which has benefits for the process simulation chain.

Paolo Guglielmini, CEO MSC Software, stated, “For MSC Software, BAE Systems Air is a great partner because it shows that we offer best-in-class solutions and with our MSC One product token system, a complete portfolio of solutions can easily be deployed that works hand in hand with BAE’s applications,”

When using Additive Manufacturing, BAE systems must face the main challenges of residual stresses and distortions. Before it employed a simulation software, the company reported, it sometimes had to complete five or six build trials, which are costly and time-consuming. With accurate simulation, it is expected to be able to reduce its build trials to just two per component, with the opportunity to eliminate build trials with a ‘right first time’ approach in future.

At this stage, the company reported that it is pleased that its Application Engineers will use Simufact Additive for the build preparation of a component in order to achieve the best orientation and support strategy for a particular build. It added that it is now able to reduce distortion in components by more than 70% at the first iteration step.

“We are proud that one of the largest defence contractors in Europe, and a company that is among the world’s largest defence entities, decided on Simufact Additive to roll out their Additive Manufacturing processes,” added Dr Hendrik Schafstall, Simufact’s CEO and Managing Director. The trust BAE have put in us reinforces our approach and the great work being done by our development team.