Automotive manufacturer uses EBAM to reduce tooling and die costs

October 18, 2016

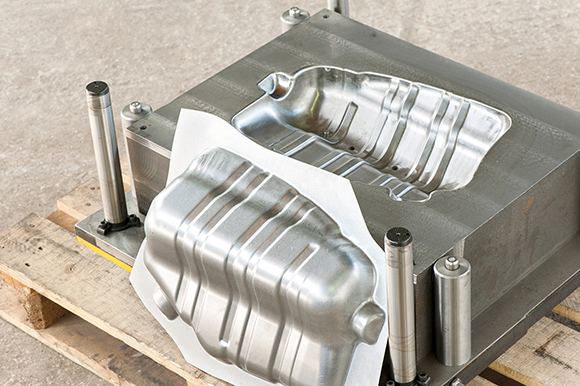

It has been reported that Electron Beam Additive Manufacturing (EBAM) technology from Sciaky, Inc., a subsidiary of Phillips Service Industries, Inc. (PSI), in Chicago, Illinois, USA, has helped a major automotive manufacturer cut significant time and costs with the creation and repair of several tooling and stamping dies.

The manufacturer has used EBAM to deposit complicated tooling features, as well as perform customised repairs and cladding operations for several high-volume parts. Following a successful proof of concept stage, the additively manufactured tool has now been brought into service.

“Sciaky’s EBAM technology is not limited to titanium parts and aerospace applications,” stated Bob Phillips, Vice President of Phillips Service Industries, Inc. “We have provided 3D printed solutions to customers in a variety of industries like automotive, agricultural, defence, nuclear, oil & gas and sea exploration using a wide variety of metals like stainless steel, tantalum, tungsten, Inconel and niobium.”

Sciaky’s EBAM systems can produce parts ranging from 203 mm to 5.79 meters in length, but can also manufacture smaller and larger parts, depending on the application. EBAM is also the fastest deposition process in the metal additive manufacturing market, with gross deposition rates ranging from 3.18 to 9.07 kg of metal per hour.