AutoAdd project looks at integration of AM in automobile series production

November 29, 2018

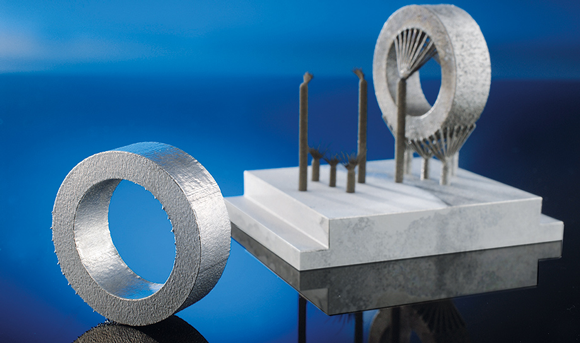

A test piece with supports removed through a wet-chemical process (Courtesy Fraunhofer ILT)

Five companies and two research institutes recently took part in AutoAdd, a project to examine the ‘Integration of Additive Manufacturing Processes in Automobile Series Production’, with a focus on Laser Beam Powder Bed Fusion (LB-PBF) technology. The project ran from June 1, 2015, to May 31, 2018, and was funded by the German Federal Ministry of Education and Research (BMBF) under its ‘Photonic Process Chains’ framework.

The full list of project partners included:

- BMW AG, Munich, Germany

- Daimler AG, Ulm, Germany (Project coordinator)

- Fraunhofer Institute for Laser Technology ILT, Aachen, Germany

- GKN Powder Metallurgy, Radevormwald, Germany

- Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany

- netfabb GmbH, Lupburg, Germany

- Trumpf Laser- und Systemtechnik GmbH, Ditzingen, Germany

BMBF’s Photonic Process Chains framework funds research projects looking to integrate photon-based manufacturing processes such as metal Additive Manufacturing into product planning to develop flexible, hybrid manufacturing conceptual designs which the industry can use to produce individualised, complex products more efficiently than previously possible.

The AutoAdd project was set up with the aim to ease the adoption of AM by the automotive industry within three years. The project partners focused on integrating the LB-PBF process into the automotive mass production environment to create a hybrid process chain and thus reduce unit costs. BMW Group and Daimler defined the requirements for an automotive Additive Manufacturing process chain, while AM machine maker Trumpf and research institute Fraunhofer ILT developed the LB-PBF plant technology.

The result was a potentially production-ready design as well as a modular system architecture which could, for example, enable the use of multiple laser beam sources and interchangeable cylinders. In addition, the project team developed automatable post-processing concepts for support structure removal, and analysed novel scalable materials produced by GKN Powder Metallurgy.

To conclude the project, Karlsruhe Institute of Technology (KIT) evaluated the new factory designs using a simulation model to visualise an exemplary conventional process chain, in which engineers at the wbk Institute for Production Science were able to design various possible LB-PBF plant concepts with methods such as cost or benchmark analysis enabling a comparison of new and previous approaches from both a technical and economic point of view.

The results of the three-year joint project were said to be impressive. Because modular cylinders and the use of wet-chemical immersion baths can now be used to remove batches of components in the post-processing step, the entire process chain can be automated and non-productive time saved, increasing the overall profitability. The AutoAdd project team has also developed common metrics for evaluating LB-PBF manufacturing equipment and identified them for the most popular equipment manufacturers as part of a large-scale benchmarking exercise.

By using standardised benchmark jobs with different test specimens, industrial users can now calculate transferable key figures with which they will be able to find the most economical system for their purposes. In addition, the reproducibility of the mechanical properties of metal AM parts – one of the most important challenges which must be overcome to make the technology ready for series production – was demonstrated and evaluated in several state-of-the-art facilities.

At the conclusion of the project, the members stated that the integration of an economical AM process chain in automotive mass production can now be considered possible. In 2019, a further project partly based on the results of AutoAdd will follow, dealing with the in-line integration of AM processes to implement the process chain designed on the project.