Aurora Labs proves Rapid Manufacturing Technology’s scalability at high build speeds

February 15, 2019

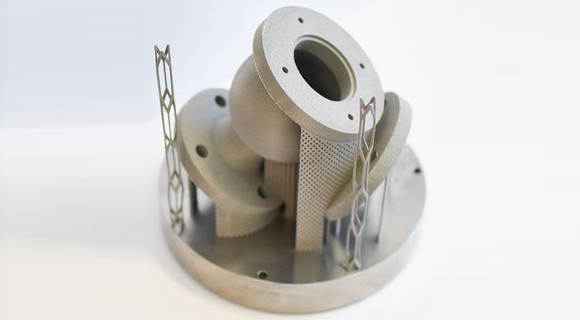

A pump valve produced using Aurora Labs’ Rapid Manufacturing Technology (Courtesy Aurora Labs)

Aurora Labs, Bibra Lake, Australia, has complete the current phase of testing for its Rapid Manufacturing Technology (RMT) for metal Additive Manufacturing, and reports that it has demonstrated the scalable nature of the technology while achieving high build speeds of 113 kg/day. According to Aurora, this makes RMT approximately fifty-five times faster than the nearest comparable machine speed (estimated to be 1.96 kg/day).

In conventional Additive Manufacturing processes, a digital part design is run through software which ‘slices’ it into a series of thin layers. The machine then deposits a very thin layer of powder on the print bed and builds the first ‘slice’ of the part using a laser or electron beam to scan the surface of the powder bed, melting and fusing the powder in the shape and dimensions of the slice. This process is repeated until every slice has been built.

By comparison, Aurora’s Multilevel Concurrent Printing (MCPTM) process deposits multiple layers of powder at the same time. During the powder laying process, building can take place behind each individual powder gate, meaning that the part build can occur on multiple operative surfaces simultaneously.

From its inception, MCP technology has reportedly been designed to be scalable to manufacturing requirements. Aurora’s Alpha machine, on which the majority of its testing is carried out, has a single sub-unit. It has now been modified to include the connection of two sub-units working together, effectively doubling the speed capacity of the single-unit configuration.

This scaling process is expected to allow Aurora to scale its process to virtually any size and capacity, with the large format said to be able to build up to 1000 kg/day with multiple sub-units contained within it. By combining MCP and its ability to scale, Aurora stated that it has identified a pathway to very high-speed large format Additive Manufacturing, providing major companies with a solution to their parts needs.

David Budge, Aurora’s Managing Director, commented, “This step in the development of the technology is the latest in a long line of impressive developments since the company’s inception in 2014. Printing on multiple levels simultaneously at high speed is what we believe will ultimately allow us to print up to 1000 kg in one day.”

“A large portion of the groups that Aurora is currently in discussion with are interested in replaceable parts and the capability of replacing them directly using Additive Manufacturing or redesigning them using the advantages of 3D printing with superior materials to deliver a superior product at a cost-competitive price,” he continued.

“The primary factor in delivering an end-product cost-competitive with traditional manufacturing is the speed of the machine. This is why Aurora is looking outside traditional 3D printing markets to sectors like mining, oil & gas, marine and automotive. The year ahead is looking extremely exciting.”