Aubert & Duval and Alloyed to discuss new Ni-based superalloy in free webinar

June 18, 2020

Aubert & Duval, a subsidiary of the High Performance Alloys Division of the Eramet group, based in Paris, France, and UK-based Alloyed,formerly OxMet Technologies, will host a webinar on July 1, 2020, to launch ABD®-900AM, a new Ni-based superalloy for metal Additive Manufacturing.

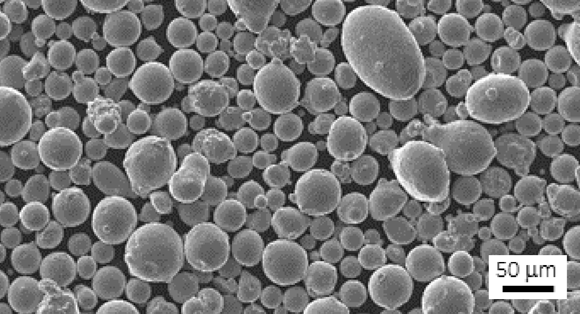

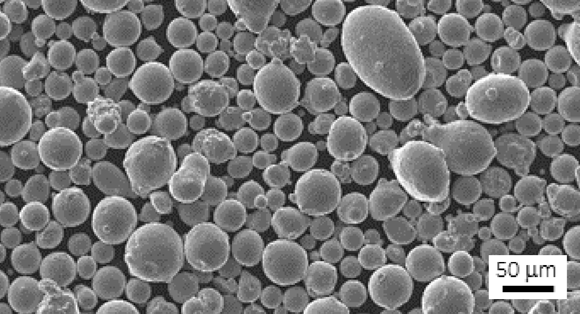

ABD®-900AM is an age-hardenable Ni-based superalloy created specifically for the AM process. The alloy is said to be designed to provide an improved combination of high strength, high creep- and oxidation-resistance, and excellent manufacturability compared with alloys commonly used for AM.. The printability of the alloy using Laser Bed Powder Bed Fusion (LB-PBF) shows high resistance to cracking and ~99.9% density.

Designed for use at temperatures up to 900°C, ABD®-900AM has been tailored for AM by Alloyed, not just for high mechanical properties, but also for excellent printability. Compared with Ni718, ABD®‑900AM provides a minimum of 30% improvement in yield stress at temperatures >800°C and a creep temperature capability improvement by up to 150°C – similar to alloy 939 and alloy 738.

During the webinar presentation, Will Dick-Cleland, Additive Manufacturing Engineer at Alloyed, and Adeline Riou, Global Sales Manager at Aubert & Duval, will provide an overview of material properties as well as various case studies of interest for space, aircraft engines, gas turbines, and motorsports.

The webinar duration is thirty minutes and is free to attend. It will take place at the following times: Central Europe Time (CET) – 17:00, United Kingdom (BST) – 16:00, North America; EasternEastern – 11:00, Central – 10:00, Mountain – 09:00, Pacific – 08:00.