ASTM unveils Additive Manufacturing operator certification

May 3, 2022

ASTM International, Conshohocken, Pennsylvania, USA, has announced the Powder Bed Fusion – Laser Beam (PBF-LB) Machine Operator Certification programme, developed by ASTM International’s Additive Manufacturing Centre of Excellence (AM CoE).

Built on the joint ISO/ASTM standard 52942:2020 for qualifying machine operators of PBF-LB Additive Manufacturing machines and equipment, the new certification is intended to provide a benchmark for assessing reliable and competent operations of PBF-LB machines.

The ASTM certification consists of both theoretical and practical assessments to evaluate the knowledge of the PBF-LB operator. The programme ensures competencies in the following:

- Additive Manufacturing Procedure Specification (APS)

- Standard operating procedures

- Machine management and build process monitoring

- Post-processing optimisation

- Operator Maintenance of systems

- Powder material family specialisations

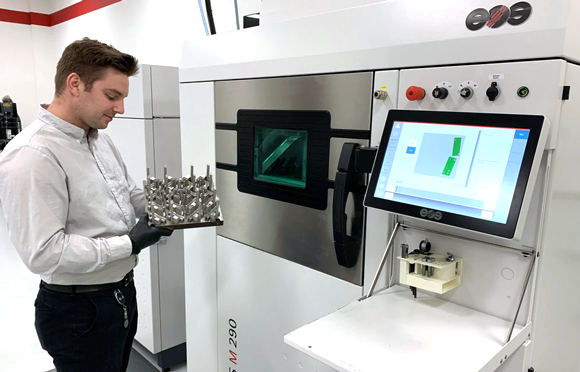

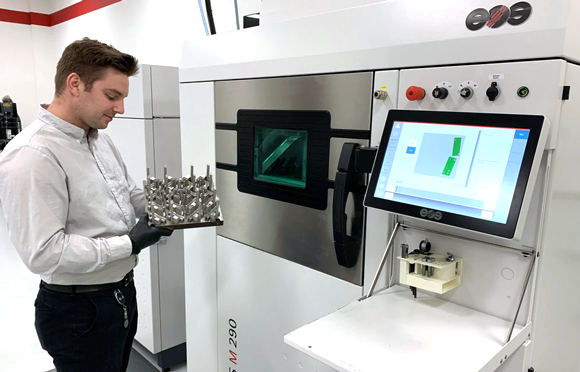

Assessments specific to machine models are required for certifying operators of a particular metal platform. Additive Manufacturing technology provider EOS GmbH, headquartered in Krailling, Germany, worked closely with ASTM to create the assessments for EOS’ metal systems and pilot the programme on its EOS M 290.

“To successfully leverage AM technologies, we must pair those who are trained, and ASTM certified, for effective, efficient, and competent machine operations,” stated Dr Gregory Hayes, senior vice president, Applied Engineering at EOS North America. “EOS is proud to serve as the first AM equipment manufacturer to offer this personnel certification programme. With ASTM, we are beginning to fill the need starting with the EOS M 290, but plan to expand certifications to cover all our metal and polymer platforms, and all material families.”

Mohsen Seifi, PhD, ASTM International’s Director of Global Additive Manufacturing Programs, added, “Certification programmes reinforce the use of standards and build trust and confidence in the use of AM technologies. This programme is one of the first steps to fulfilling industry personnel certification needs and we look forward to quickly expanding to other machine vendor platforms. Together with key industry stakeholders, we can support reliable and competent use of the technology.”

More information on, and registration for, the certification programme is available via the EOS e-store or the AM CoE website.