Amnovis and BAAT Medical partner to streamline medical AM development

June 15, 2022

Amnovis, Aarschot, Belgium, and BAAT Medical, Hengelo, the Netherlands, have partnered to offer a fast turnaround process for additively manufactured medical devices. Both companies aim to jointly span the complete process, from initial design idea over medical engineering to approved devices ready for medical use.

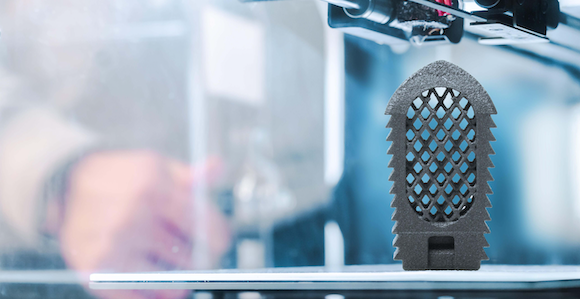

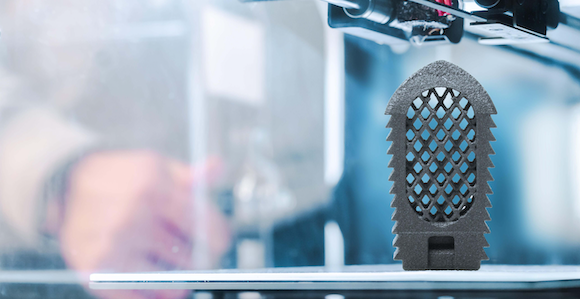

BAAT Medical has been working in the engineering and development of additively manufactured spinal fusion implants, resulting in multiple CE marks and FDA approvals and more than 50,000 implants manufactured to date. The Amnovis’ founders have a proven track record, going back to 2008, in using Additive Manufacturing to make high-end products. This company was reputedly among the first to employ Laser Beam Powder Bed Fusion (PBF-LB) for additively manufactured titanium medical devices, such as orthopaedic and spinal implants.

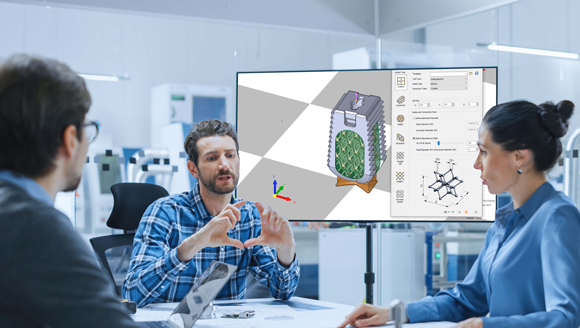

Together, the companies intend to have a comprehensive view of how to optimally tune design & development, as well as material selection and manufacturing in the context of specific additively manufactured medical device applications. Both companies work on a joint technology and application roadmap and actively validate new Additive Manufacturing technologies to set new standards for specific medical device types. These efforts align with the business potential and time to market of new AM technologies in the medical sector. As part of this effort, the companies focus more intently on AM materials and post-processing methods, as well as process automation and validation.

“We are extremely proud to collaborate with BAAT Medical,” stated Ruben Wauthle, CEO and co-founder of Amnovis. “We see great potential in jointly innovating various AM medical device applications. We know each other for years, share the same innovative drive, and collaborate intensively to better align design and development with material selection and manufacturing. As preferred partners, our joint offering comprises of the complete process for customers and prospects to aim high and move fast, while removing hurdles in medical device development, validation and manufacturing. At Amnovis, we rely on our comprehensive AM workflow and production platform, which is entirely ISO 13485:2016 certified. Digital process automation enables us to provide full traceability and repeatability to flexibly scale up manufacturing of standard and patient-specific AM medical devices.”

Gert Nijenbanning, Managing Director of BAAT Medical, added, “It is great to intensify our collaboration with the AM innovators of Amnovis, with whom we successfully worked with before. We believe that efficiency in development and production throughout the whole chain is essential to keep investments in innovations of medical devices feasible, especially for European markets where the MDR is a reality. Together, we want to build on the complementary expertise of Amnovis and BAAT Medical to collaborate and take 3D printing of medical devices to the next level.”