AML3D to implement Industrial Internet of Things technology into its WAM machines

September 8, 2020

Australian-based AML3D Limited has entered into a Memorandum of Understanding (MoU) with the Advanced Manufacturing Growth Centre (AMGC) and Dematec Automation Pty Ltd (Dematec) to co-develop Industrial Internet of Things (IIoT) solutions for AML3D’s Adelaide Production machine modules and Arcemy® Wire-Arc Additive Manufacturing (WAAM) units.

The project aims to deliver a solution that enables AML3D’s distributed manufacturing business model strategy, enabling the deployment of Arcemy units close to customer sites globally. AML3D’s engineers and technicians will then be able to centralise control of deployed Arcemy models via ‘printing module dashboards’ to allow local production of parts manufacturing on demand for its customers.

This initiative includes enabling an artificial intelligence capability in line with AML3D’s product development roadmap to enable smarter machines in line with the market’s anticipated development over the next three to five years.

AML3D intends to use these technologies to drive efficiencies internally and externally to deliver a fully integrated customer service solution, capable of:

- Centralised remote operation of Arcemy units deployed globally based on customer location demand

- Deployment of a future ‘virtual warehouse’ of parts for customers

- Enabling artificial intelligence interfaces as part of the AML3D product development roadmap to optimise the print process

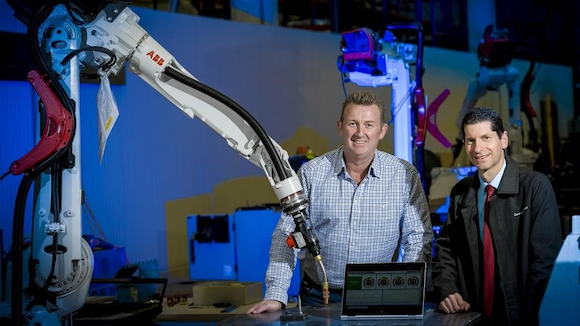

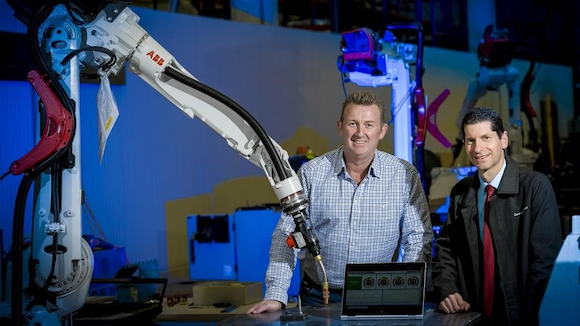

Andrew Sales, AML3D’s managing director, commented, “We’re eager to embark on this program with two highly regarded innovation partners. The enhanced capabilities of the proposed platform will provide us with complete oversight of all production units globally.”

“A greater level of live insight is key to driving efficiencies, both internally and externally,” he continued. “Once integrated, the platform will only further imbed our technologies within our clients’ operations, solidifying AML3D as a core advanced manufacturing partner.”

David Hart, Dematec CEO, commented, “At Dematec, we’re focused on pushing the Australian manufacturing sector to the forefront of innovation. AML3D is a great example of Australian ingenuity, and we’re excited to embark on a co-development program that will only further enhance their offering.”