AML3D commences aerospace certification

July 25, 2022

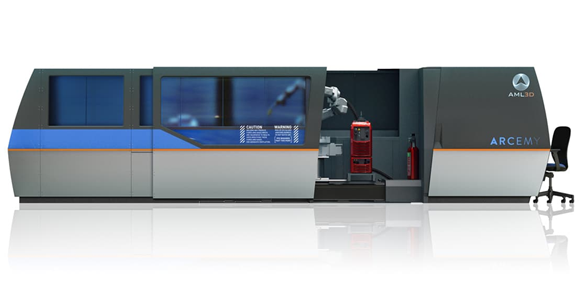

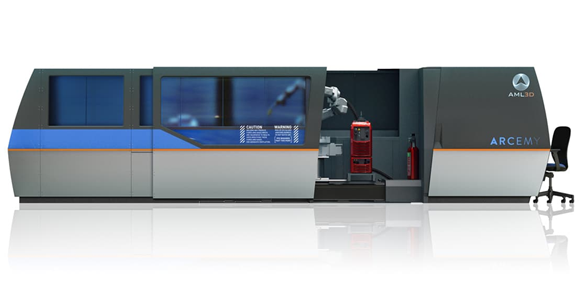

AML3D Limited, Edinburgh, Australia, has announced that it will be commencing implementation of the Aerospace Quality Management System AS9100D:2016 Accreditation, which will allow the company to manufacture ‘fly parts’ for use in aircraft. AML3D utilises a patented Wire Additive Manufacturing (WAM) process, also known as Wire Arc Additive Manufacturing (WAAM), a wire-based form of Directed Energy Deposition (DED).

Achieving the accreditation will enable the company to demonstrate it has achieved a benchmark consistent performance and service, meeting and exceeding customer, statutory and regulatory requirements. AS9100D:2016 accreditation is said to be in line with the company’s growth strategy to increase sales of existing products and initiate sales of new products to the aerospace & defence industries.

“Implementation of AS9100D certification will further demonstrate AML3D’s commitment to delivering the highest quality components into the aviation, space and defence industry,” stated Andrew Sales, Managing Director, AML3D. “This is an important step in our growth strategy for the company as we pursue high value contracts for aerospace. We are excited to further progress into the aerospace industry with our technology, further validated by this certification.”

The process for accreditation is expected to be completed in the second half of the 2023 financial year, at a cost of approximately $25,000, with funding sourced from AML3D’s recent growth-initiative capital raising. Once implemented, AML3D would reportedly be the second wire-based feedstock Additive Manufacturing company to achieve the standard.