AMFG upgrades its Additive Manufacturing workflow automation software

May 10, 2019

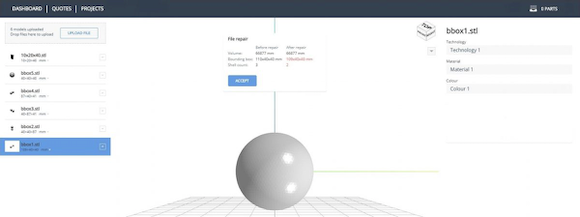

AMFG’s Request and Ordering Portal is said to provide a customisable and flexible solution for OEMs and service bureaus (Courtesy AMFG)

AMFG, London, UK, a provider of workflow automation software for Additive Manufacturing, has upgraded its workflow software platform with the addition of a new Request and Ordering Portal. This new feature automates the request and order handling process for OEMs and service bureaus.

“The ability to standardise the process of receiving incoming requests or orders for parts is the first step to establishing an agile and scalable Additive Manufacturing process,” explained Felix Doerr, AMFG’s Head of R&D and Partnerships. “Our Request and Ordering Portal gives businesses the flexibility to eliminate the intrinsically manual nature of this process through automation.”

The Request and Ordering Portal is part of AMFG’s modular, end-to-end workflow software platform. For OEMs, the portal, which can be customised to any type of workflow process or application, is said to offer a flexible way for AM departments to standardise the request management process.

“The vast majority of companies are struggling to streamline the way in which they receive requests for parts internally, and this is compounded when AM operations are spread across multiple locations,” continued Doerr. “Our portal helps to standardise the data that can be submitted to the AM or RP department from the outset, and automates the process so that machine operators no longer have to spend a huge proportion of their time on manually verifying each individual request.”

The flexibility of the new upgrade is also said to make it possible for service bureaus to use the portal to offer an enhanced digital experience for their customers. “Other solutions on the market are often difficult to use and offer a poor user experience,” Doerr stated. “We’ve ensured that our new Request and Ordering Portal includes functionality that will enable service bureaus to communicate more easily with their customers and offer an unmatched user experience.”

“Having customers within both the OEM and service bureau markets, we’re continually striving to develop a product that offers the flexibility required to serve the needs of both markets and their unique workflows. Ultimately, our vision behind the new Request and Ordering Portal is to ensure that AMFG continues to provide the most flexible, customisable workflow software solution on the market,” he concluded.