Aluminium Materials Technologies Ltd now transferred to Eckart

August 25, 2021

Following the announcement last year that Germany’s Eckart Group, a company of Altana AG, was to acquire Aluminium Materials Technologies Ltd. (AMT), Worcester, UK, the company has reported it has now completed integration and business operations will be transferred to Eckart on October 1, 2021.

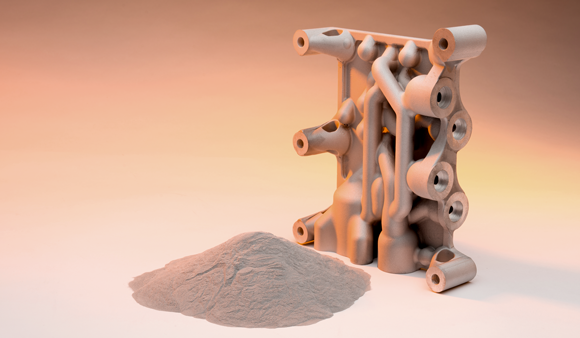

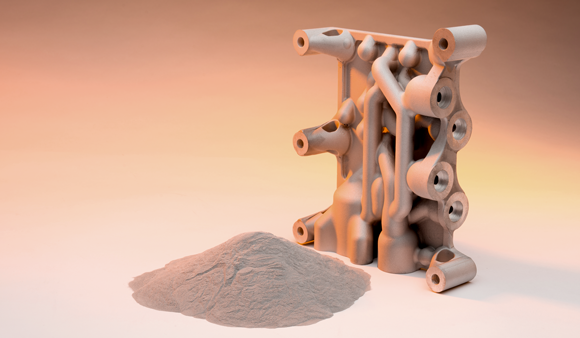

Eckart will continue to supply the full range of AMT products, notably the established A20X powder for Additive Manufacturing and A205 alloy for foundries. AMT shipments will be serviced by Eckart starting on September 1, 2021.

AMT developed the A20X special alloy for Additive Manufacturing, which is said to enable the manufacturing of significantly lighter components with outstanding mechanical properties. It recently secured aerospace recognition with the publication of AMS7033 standard for its high-strength and high-temperature.

Eckart is one of the world’s leading manufacturers of effect pigments, with almost 150 years of experience in the production of powders. Specialised in the atomisation of metal and in particular in the production of aluminium powders, Eckart provides an annual capacity of more than 10,000 metric tons.