Alphacam signs exclusive distribution agreement with Tritone

June 21, 2021

Additive Manufacturing services provider Alphacam GmbH, Schorndorf, Germany, has signed an exclusive distribution agreement with Tritone Technologies, Petach-Tikva, Israel. Through the agreement, Alphacam extends its range of metal AM machines offered in Germany, Austria, Switzerland and Lichtenstein.

Alphacam has nearly three decades of experience in Additive Manufacturing, and has been a sales partner of Stratasys in Germany since 1994 – this, states the company, has illustrated a proven distribution structure. During the intervening years, the company has grown to have its own training and presentation centres, a service hotline and a professional AM service.

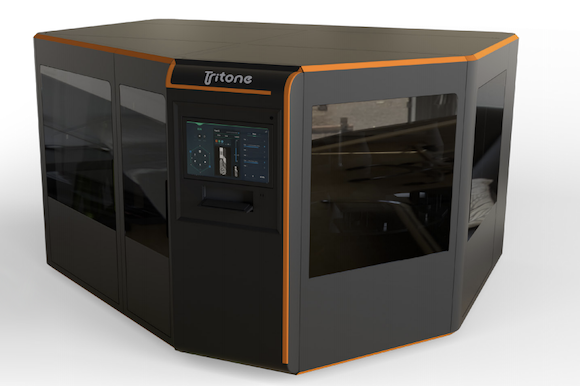

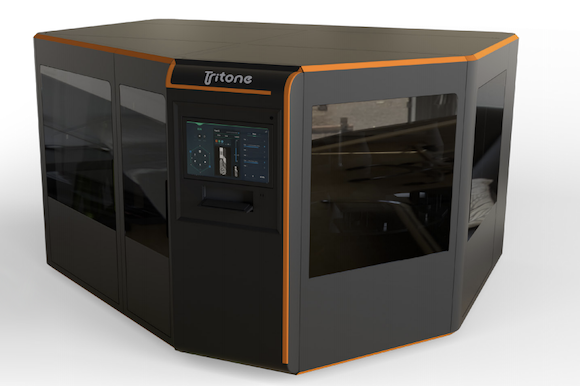

Tritone Dominant is a powder-free AM system that enables industrial production of high-quality metal parts. The system is based on Tritone’s patented and patents pending MoldJet® technology, built for producing large quantities of high-density parts with complex geometries.

Since its introduction at the Formnext 2019 exhibition, the Dominant system and the MoldJet technology is said to have been improved, increasing its set of available metal and ceramic materials to address the rigorous requirements of industrial applications. The enhancements include advanced verification of build quality, precision and uniformity, higher throughput and improved streamlined post-process of parts.

“We were fascinated by the idea Tritone innovated by using the well-known MIM powders in an industrial ‘powder-free’ AM process. For our customers it will be a big advantage handling only a clean and safe metal paste to receive strong dense green parts,” stated Michael Junghanss, Managing Partner at Alphacam.

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Dresden was the first European user of this system, installed at ICAM®, the Innovation Center Additive Manufacturing.

Thomas Weissgärber, head of Fraunhofer IFAM Dresden, commented, “With our research and development work, we want to transfer Additive Manufacturing into a broad industrial application. We are looking forward to contributing to this strategic partnership with our know-how and to developing innovative material and component solutions.”