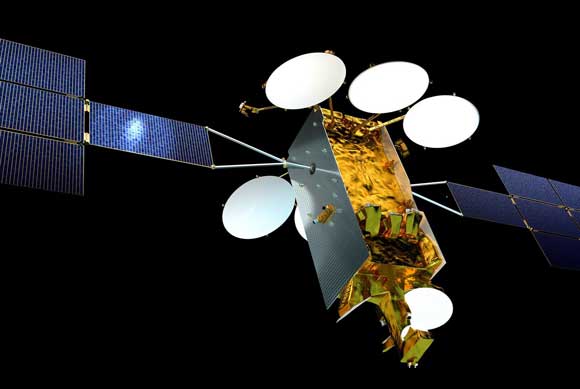

Airbus additively manufactures 500 radio frequency parts for two Eurostar Neo satellites

February 19, 2021

Airbus has additively manufactured a total of 500 radio frequency (RF) components, composed of multi-waveguide blocks and switch assembly networks, at its Airbus Defence and Space site in Portsmouth, UK, for two of its Eurostar Neo spacecraft that will join the in-orbit fleet of Eutelsat, a leading provider of satellite communications services headquartered in Paris, France.

The two satellites, called EUTELSAT HOTBIRD 13F and 13G, are expected to reinforce and enhance Eutelsat’s TV broadcasting services over Europe, the Middle East, and North Africa.

By utilising Additive Manufacturing for the satellites, Airbus stated there were major labour savings and a significant reduction in the number of individual required parts.

Gareth Penlington, the HOTBIRD Payload Manager at Airbus, commented, “This is recognised as the first large-scale deployment of RF products using the ALM process, and it puts us in an industry-leading position for the technology’s application in producing radio frequency components.”

Airbus’ manufacturing team in Portsmouth developed innovative designs for the Eurostar Neo’s multi-waveguide blocks and switch assembly networks to be additively manufactured, taking them from initial concept and patenting through industrialisation and the completion of a successful qualification programme.

The first EUTELSAT HOTBIRD satellite’s communications module was transferred in early February from Portsmouth to the Airbus Defence and Space facility in Toulouse, France, where the spacecraft’s full build-up will be completed. Assembly of the second HOTBIRD communications module is now underway in Portsmouth, with its testing scheduled this month.

Penlington added, “This is recognised as the first large-scale deployment of RF products using the ALM process, and it puts us in an industry-leading position for the technology’s application in producing radio frequency components.”