Admatec adds vision-based process monitoring for metal & ceramic Additive Manufacturing

September 6, 2019

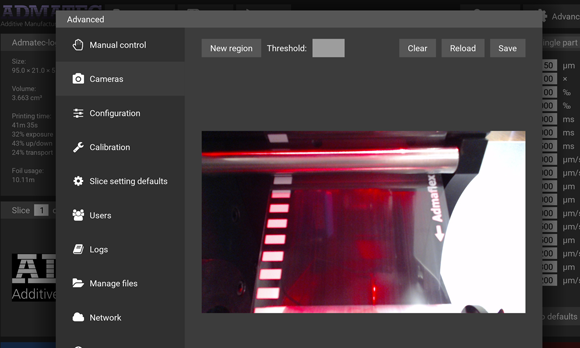

Admatec Europe BV, Goirle, the Netherlands, has added vision-based process monitoring to its Admaflex 130 machine for metal and ceramic Additive Manufacturing. The new feature has been specifically designed for highly demanding fields such as the aerospace, biomedical and aesthetic (cosmetic) industries, wherein high productivity and full traceability are required.

The vision-based system is said to allow a higher degree of user control for the AM of metal and ceramic components through layer detection, foil movement and time-lapse videos of builds. The result is that, should one build in a series of 180 fail, the monitoring system will detect this and rectify the failure for the remaining 179 parts, saving the time and financial costs of a larger-scale build failure.

Jaco Saurwalt, COO at Admatec, stated, “We are constantly working to improve, not only with new hardware and material development but also in functionality and productivity, through software updates that aim at benefitting our existing customer base while improving the efficiency of the technology.”

With the vision-based monitoring system, Saurwalt explained, “Our customers are now able to trace back each step of the print with additional log files that work as proof of the AM process particularly needed for biomedical and aerospace applications.” While the monitoring system is currently available to Admaflex 130 users as an add-on, it was stated that future machines in the Admaflex series will be equipped with it as standard.