AddUp participates in $1.5M research program to advance IN-718 Additive Manufacturing for the United States Air Force

May 23, 2023

AddUp Inc., headquartered in Cébazat, France, has joined a $1.5M research contract entitled “Development of Manufacturing, Heat Treatment, and Surface Finishing Guidelines to Yield Ready-to-Use IN-718 Additive Manufacturing Components” through the United States Air Force (USAF) and the Small Business Innovation Research (SBIR) programme led by REM Surface Engineering (REM).

The project is funded through a Direct to Phase II Small Business Innovation Research (SBIR) contract and aims to harness the potential of Laser Beam Powder Bed Fusion (PBF-LB) and surface finishing technologies to produce IN-718, a nickel-base superalloy, components for legacy armament systems. The endeavour looks to research the impact of various heat treatment and build parameter combinations in association with REM’s surface finishing technology on a component’s mechanical properties such as tensile strength and fatigue life. Both AddUp and Zeda are supporting this project, which aims to provide the USAF with a set of manufacturing guidelines that maximise the capabilities of PBF-LB to meet fleet readiness and sustainment goals.

Fatigue strength plays a critical role in ensuring the longevity and reliability of components used within the USAF. AddUp claims that the combination of fine powder and a roller recoater in its FormUp 350 machine provides a synergistic effect on surface finish improvement, leading to enhanced fatigue properties in IN-718 material. Fatigue resistance can be considerably improved by the reduction of surface irregularities, minimising defects and achieving a more uniform powder layer. This is particularly crucial in aerospace and defence applications, where fatigue performance is critical for long-term structural integrity and operational reliability.

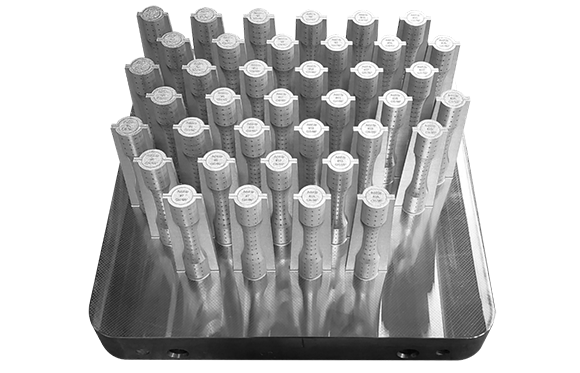

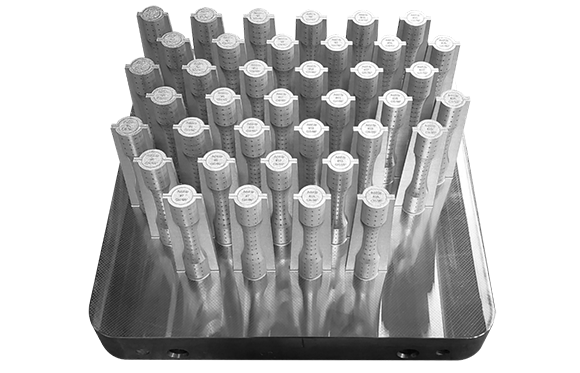

Fatigue testing is, therefore, crucial in ensuring the reliability and integrity of IN-718 components. IN-718 fatigue specimens will be manufactured by Zeda using an AddUp FormUp 350 machine. These will then be utilised in REM’s testing matrix to establish expected material properties of PBF-LB components with varying levels of surface finish and different manufacturing and heat treatment parameters. Through this collaborative effort, the project seeks to validate the fatigue strength of IN-718 AM components manufactured using AddUp’s technology.

By leveraging the capabilities of PBF-LB technology and conducting rigorous fatigue testing, this project strives to enhance the performance, reliability, and cost-effectiveness of aerospace and defence components reducing downtime and enable mission-critical operations to proceed smoothly.

Download Metal AM magazine