Additively manufactured tracheal stents may allow children to breathe easier

February 5, 2021

New research published by University of Pittsburgh, Pennsylvania, USA, illustrates a possible improvement in the use of medical stents, demonstrating the successful use of a completely biodegradable magnesium-alloy tracheal stent that avoids some of the risks posed by more traditional material.

Pediatric laryngotracheal stenosis (LTS), a narrowing of the airway in children, is a complex medical condition which can result in a life-threatening emergency if untreated. Still, treatment is difficult: depending on severity, doctors are left to balance a combination of endoscopic techniques, surgical repair, tracheostomy and/or stents to allow better airflow.

Stents are great at holding the airway open while still allowing the trachea to grow, but they do present problems with the inability to shift and the possibility of causing damage when removed.

“Using commercial non-biodegradable metal- or silicone-based tracheal stents has a risk of severe complications and doesn’t achieve optimal clinical outcomes, even in adults,” stated Prashant N Kumta, Edward R Weidlein Chair Professor of bioengineering at the Swanson School of Engineering, the University of Pittsburgh’s engineering school. “Using advanced biomaterials could offer a less invasive, and more successful, treatment option.”

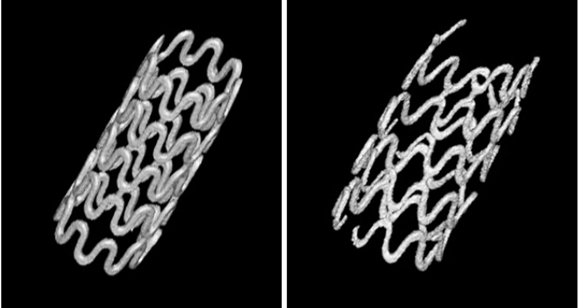

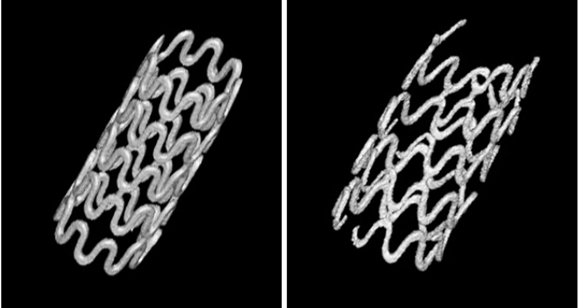

In order to manufacture the stent, as-cast LZ61-KBMS was extruded into a micro-structurally refined rod, 20 mm in diameter. The resulting rod was then fabricated into mini tubes via wire Electric Discharge Machining (EDM), before being laser cut following a programmed pattern in order to give the rods granular surfaces, rather than the traditionally-smoother wire-EDM cut surfaces.

After this, the stents were electrochemically polished, hooking them up to a pure Mg wire connected to a DC anode, thus reducing inhomogeneous polishing at contact spots and producing polished stents with smooth metallic lustres.

In the study, the balloon-expandable ultra-high ductility (UHD) biodegradable magnesium stent was shown to perform better than current metallic stents in use in both lab and rabbit testing. This new stent was able to keep the airway open over time and have low degradation rates, displaying normal healing and no adverse affects.

“Our results are very promising for the use of this novel biodegradable, high ductility metal stent, particularly for paediatric patients,” added Kumta. “We hope this new approach leads to new and improved treatments for patients with this complex condition, as well as other tracheal obstruction conditions, including tracheal cancer.”

The paper, ‘In-vivo efficacy of biodegradable ultrahigh ductility Mg-Li-Zn alloy tracheal stents for pediatric airway obstruction’, was authored by the Swanson School’s Jingyao Wu, Abhijit Roy, Bouen Lee, Youngjae Chun, William R. Wagner, and Prashant N. Kumta; UPMC’s Leila Mady, Ali Mübin Aral, Toma Catalin, Humberto E. Trejo Bittar, and David Chi; and Feng Zheng and Ke Yang from The Institute of Metal Research at the Chinese Academy of Sciences.