Additive Rocket Corporation to implement Link3D’s Manufacturing Execution System

May 1, 2019

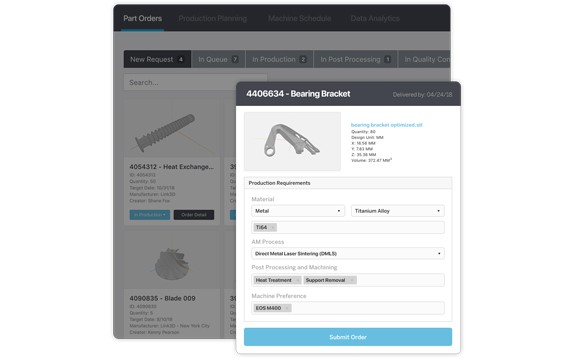

Link3D’s AM-focused Manufacturing Execution System (MES) (Courtesy Link3D)

Link3D, New York City, USA, has announced its partnership with Additive Rocket Corporation (ARC), San Diego, California, USA, at AeroDef, which is being held at the Long Beach Convention Center, Long Beach, California, USA, from April 29–May 2, 2019. ARC is an aerospace company that produces metal additively manufactured rocket engines for the expanding space industry. The partnership will reportedly enable the introduction of Link3D’s AM-focused Manufacturing Execution System (MES) into ARC’s workflow, which will allow the company to streamline its Additive Manufacturing production and implement a data-driven approach. It is also expected to allow the company to consistently follow, enforce, and comply to regulatory authorities including SAE International, NASA and AS9100 standards.

According to Link3D, as Additive Manufacturing matures, knowledge gaps in standardising process parameter sensitivity, mechanical properties, machine calibration / maintenance, vendor quality approvals, and other risks associated with the production of high-quality parts are becoming more defined. The company has stated that it will enable its workflow software to ensure the ability to track and trace data in a secure environment to help organisations like ARC prove, simplify and integrate quality management into AM.

“Link3D is the perfect compliment to our design process, streamlining our manufacturing operations and building quality into the workflow. Link3D’s Standards Compliance Program is a built-in solution of its Additive Manufacturing workflow software that tremendously helps organisations in aerospace & defence increase productivity and reliability, improve its market position, reduce costs and advance new technologies,” stated Kyle Adriany, Co-Founder & CTO of ARC.

Vishal Singh, CTO of Link3D, commented, “We are excited to announce our partnership at Aerodef, surrounded by aerospace and defence organisations and satellite startups to share the possibilities of AM technology. Link3D and ARC’s collaboration has a mission to streamline regulatory compliance for Additive Manufacturing by making it seamless for organisations to take advantage of Link3D for data traceability, and document tracking through various stages of AM.”

Adherence to quality control and QA requirements from each regulatory standards board (e.g., SAE, NASA, AS9100, ISO 9001) is expected to be embedded into Link3D’s Additive Manufacturing workflow solution to trace and track governing standards. Other major sectors that are integrating Link3D’s Additive MES workflow software include aerospace & defence, government, automotive and medical industrial.

“ARC’s mission is to democratise space by providing reliable and affordable propulsion solutions. Additive Manufacturing has been around for decades, but our industry is just beginning to embrace the technology. Engineers were designing for manufacturability. We are now designing for optimisation and that is what makes it revolutionary,” reported Andy Kieatiwong, Co-Founder and CEO of ARC.

Shane Fox, CEO & Co-Founder of Link3D, stated, “We are humbled to collaborate with such brilliant and forward-thinking minds at ARC. We are proud to call ourselves partners as we push the boundaries of AM. ARC’s approach to design for Additive Manufacturing of rocket engines and unique business model will surely disrupt the way rockets are launched into space.”