Additive Industries launches new Product Removal Module and software at formnext

November 17, 2017

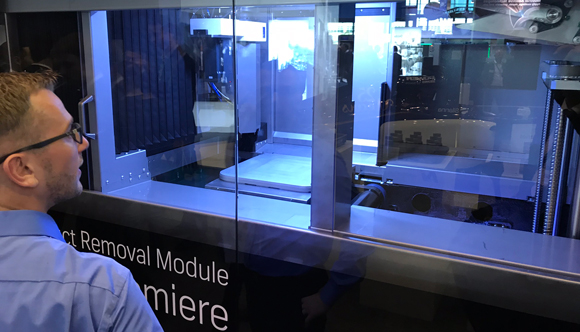

Additive Industries launched its new Product Removal Module during formnext powered by tct 2017

Additive Industries, Eindhoven, the Netherlands, launched its new Product Removal Module during formnext powered by tct 2017. This module will allow users of the company’s MetalFAB1 system to remove products from the build plate, release any trapped powder and resurface the build plate by 3-axis milling for reuse.

According to Additive Industries, this will prevent the need for time-consuming logistics and external post-processing. Additive Industries also presented its Dynamic Laser Allocation software, which is used to control four full-field lasers working on a single part or multiple products.

The software contains a smart algorithm which optimises laser allocation for a customer-set balance between quality and productivity. A specific feature of the software is the ability to dynamically prevent lasers from melting in the smoke of another laser, which may help ensure part quality.

During formnext, Additive Industries also announced that it will offer ten potential new users of its technology to enter into an Industrial Additive Manufacturing Program. This programme offers attractive conditions for the purchase of a user’s first MetalFAB1 system, in combination with full support for process implementation and application development.

Daan A.J. Kersten, CEO of Additive Industries, stated, “We want to support professional OEMs and their 1st tier suppliers to scale for production with our integrated metal Additive Manufacturing systems, and recognise that help from our Process & Application Development team will accelerate part identification, design for AM as well as implementation of the technology.”