ADDere to offer Additive Manufacturing services to its customers

March 22, 2019

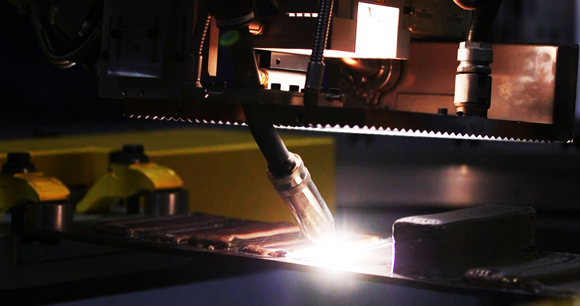

ADDere develops wire-based metal Additive Manufacturing technology (Courtesy ADDere)

ADDere, the Additive Manufacturing System division of Midwest Engineered Systems (MWES), Waukesha, Wisconsin, USA, is expanding to offer metal Additive Manufacturing production services to its customers, using its in-house wire-based AM systems. Prior to the announcement, the company focused on sales of its ADDere I, II and III machine systems.

Pete Gratschmayr, ADDere’s VP of Sales & Marketing, stated, “We’ve expanded into providing printing services as well as selling complete Additive Manufacturing systems as a way to open up this technology to firms who may not have the throughput to make the capital investment but would like utilise its capabilities. The service is also a great way for firms to test out the process before making the investment. We’re confident ADDere printing services will exceed expectations.”

MWES developed its AM process for the production of components in exotic metals including yitanium, duplex stainless steel and other super alloys. However, it can also be used to deposit new metal structures on components made by other processes, such as casting, machining or forging. The material deposition process reportedly makes production runs with small part variations more economical,as well as allowing for the repair of large metal components.

“We see this technology opening a lot of doors in manufacturing large, complex and high-performance components for a number of industries – and others have too,” commented Scott Woida, ADDere CEO. “We’re excited to offer our knowledge and ability as a service to customers and see where we can take the technology.”