Ad-Proc-Add project studies additive-subtractive manufacturing process chains

June 8, 2022

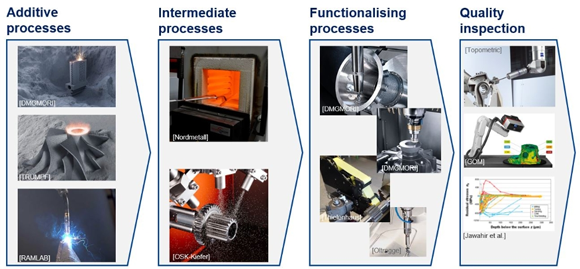

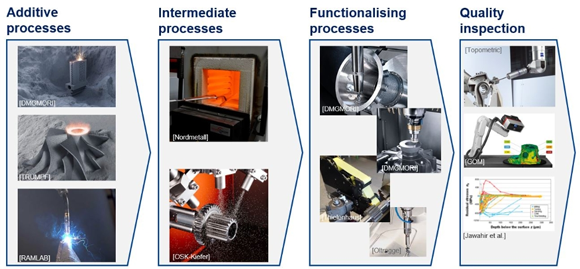

The Stuttgart Institute for Machine Tools (IfW), Germany, has been spearheading an international network researching new processes for additively manufactured parts, in the EU’s Ad-Proc-Add (Advanced Processing of Additively Manufactured Parts) project, since 2019. The project goal is to influence workpiece properties by adapting additive-subtractive manufacturing process chains, allowing the resultant pieces to meet strict engineering specifications.

According to the IfW, over 90% of additively manufactured components require some form of post-processing, in order to meet exacting tolerance requirements, before being assembled or installed. This means that Additive Manufacturing processes must be optimised so that additively processed materials can be suitably machined without negatively changing the properties of the material and/or component.

“When we refer to additive component manufacturing, in most cases we’re talking about an additive-subtractive process chain,” stated Professor Hans-Christian Möhring, Director, IfW.

This makes it important to determine how the component properties of tools, for example, can be adjusted technologically so that they meet strict requirements, despite the use of two different manufacturing processes.

Möhring stresses that all parameters must be considered, including the support structures, because they affect the microstructure and grain density. This microstructure, in turn, determines which residual stresses are introduced to the component – which can have a major impact later on in the process chain. But those who know how to influence such properties are able to produce components with unexpected properties.

“We deliberately printed highly porous elements,” Möhring stated. “In fact, porous materials are particularly suitable for support structures that have to be removed after the layering. These are examples of useful interactions.”

However, interactions also result from the design of the Additive Manufacturing process. This design determines the initial conditions of the subsequent metal post-processing.

“Depending on the microstructure of the additively manufactured component, the machining process interacts with it at the thermomechanical level. A further new microstructure then arises in the edge zones of the component,” reported Möhring. “All of these relationships needed to be investigated in order for us to understand and describe them.”

Methods for process monitoring and quality inspection were also developed in the project. The aim here was to make optimum use of the synergies with, and capacities of, the project partners.

Möhring added, “We also want to integrate measurement systems into machine and plant technology or into construction platforms in order to observe the actual 3D printing of the component and the physical effects that occur.”

This is where digital tools come into play. These include everything from digital process monitoring and control, artificial intelligence and machine learning through to physics-based analytical models, simulations and digital twins.

For Möhring, even more important than experience with digital tools, is the knowledge acquired in the projects. “This allows us to support all those involved in the ASM [additive-subtractive manufacturing] process chain – everyone from machine and plant manufacturers through to end users.“

Current Additive Manufacturing applications will be on show at METAV 2022, which will be held in Düsseldorf on June 21–24.