Aconity3D and Equispheres report faster speeds for metal AM

November 18, 2021

Equispheres, Ottawa, Ontario, Canada, and Aconity3D, Herzogenrath, Germany, have reported breakthrough speeds in aluminium part Additive Manufacturing using an Aconity3D 1 kW MIDI Laser Beam Powder Bed Fusion (PBF-LB) machine and Equisphere’s aluminium powder.

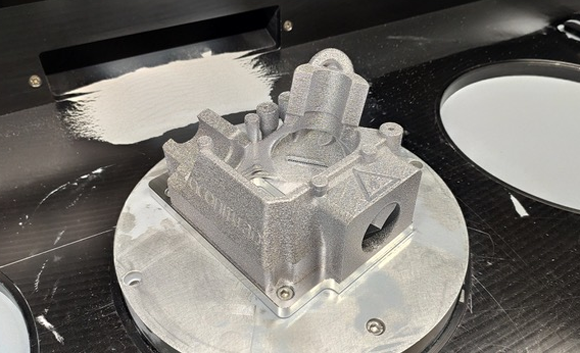

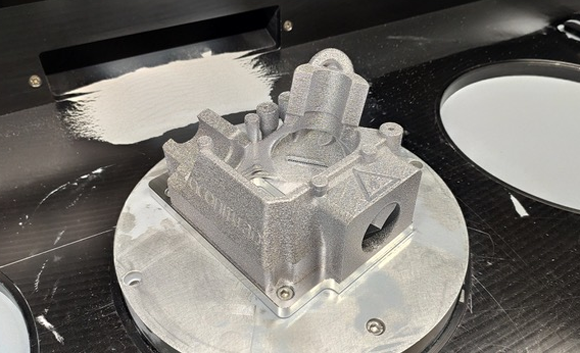

Aconity3D has been testing Equispheres powder to produce a part of the AconitySCAN, a key component of its AM machines, in hopes of producing the parts quicker and at a lower cost than the company has found achievable with standard powder. To date, the results achieved are said to have demonstrated that the desired part can be produced in over 60% less time (i.e., from fifty-three hours down to seventeen and a half hours) with no impact on mechanical properties.

“This dramatic reduction in production time reduces the cost to produce the part by greater than 50%. More importantly, it enables Aconity3D to produce our printers more quickly and meet the growing demand for our systems,” stated Yves Hagedorn, Managing Director of Aconity3D.

Evan Butler-Jones, Director of Applications Engineering at Equispheres, has expressed his belief that this feat was achieved through the use of highly spherical, uniform Equispheres powder, which is able to absorb the energy from the 1 Kw laser without disturbing the melt pool, something he has stated isn’t achievable with standard aluminium powders.

“We are pleased to partner with Aconity3D on this initiative,” he added. “Combining their expertise with AM systems and our expertise in powders provides a powerful solution to the market.”

Aconity3D intends to conduct additional testing with Equispheres powder in an effort to further optimise its process and reduce costs. In addition to using the powder for their internal part production needs, the companies are said to be finalising an agreement to enable Aconity3D to provide Equispheres powder directly to its own customers as a starter kit.

“We want our customers to have the best production experience when they utilise our specialised printer equipment. The best way to showcase our devices is to equip them with the best powder,” Hagedorn concluded.

Both companies are currently at Formnext. Aconity 3D is located in Hall 11, D39; Equispheres, 11, D54. Each booth is showcasing the new AM part.