3YOURMIND offers guide to building a digital warehouse

July 15, 2020

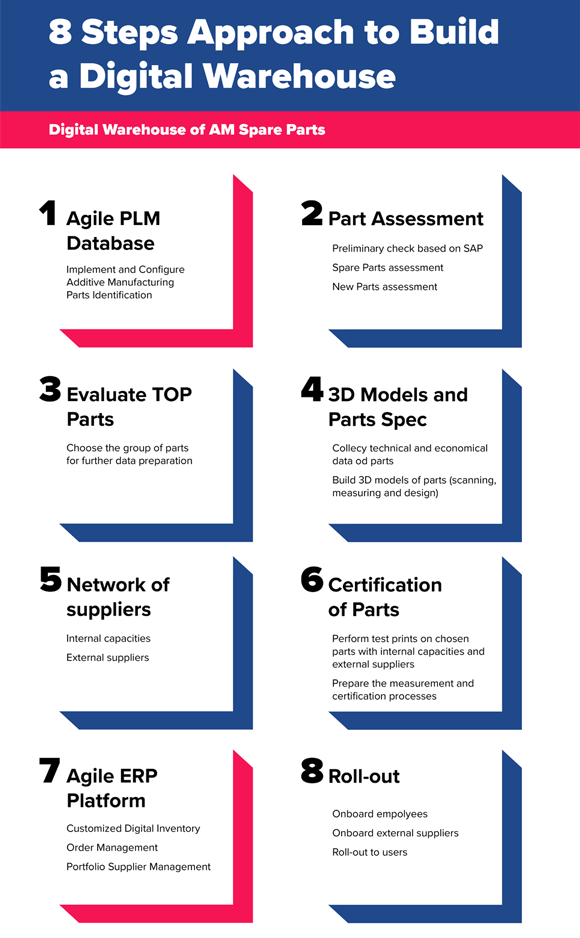

Additive Manufacturing software provider 3YOURMIND, Berlin, Germany, has published a blog post which provides an overview of how to build a digital warehouse, with the aim of increasing efficiency and identifying opportunities for improvement and self-resilience.

The post centres around the maintenance, repair and overhaul (MRO) sector, and highlights a number of examples from aerospace, oil & gas and rail industries.

According to a report by Airbus, the aviation MRO market is expected to double in the next twenty years. What is currently estimated to be a $60 billion industry in 2020, the report states, is projected to exceed $120 billion annually by 2040.

In its overview, 3YOURMIND discusses an example from French oil & gas company Total, in which the adoption of Additive Manufacturing enabled the company to limit drilling rig downtime by producing repair parts locally on-demand, and bypassing expensive logistical and shipping costs. Also cited are examples from Lufthansa, Pratt & Whitney, the US Navy and Deutsche Bahn.

The report explains that MRO supply chains are currently tasked with finding alternative ways to produce parts that will lead to cost savings for themselves and their partners. 3YOURMIND states that early adopters are making substantial changes to the way they do business, and that if the supply chain cannot keep up, they will be left behind.

The digital warehouse

The digital warehouse is an ever-evolving concept that manufacturers, production facilities and supply chain managers are adopting to increase efficiency and lower overhead costs. In this concept, instead of stocking a physical warehouse with quantities of spare parts that may never be used, facilities digitally store production files for Additive Manufacturing on-demand in when/if scenarios.

Each industry will face its own unique challenge building its own version of the digital warehouse, 3YOURMIND notes. However, regardless of industry, all MRO facilities will require assistance when it comes to identifying the best parts for transition to AM, and those which will provide the best economic return.

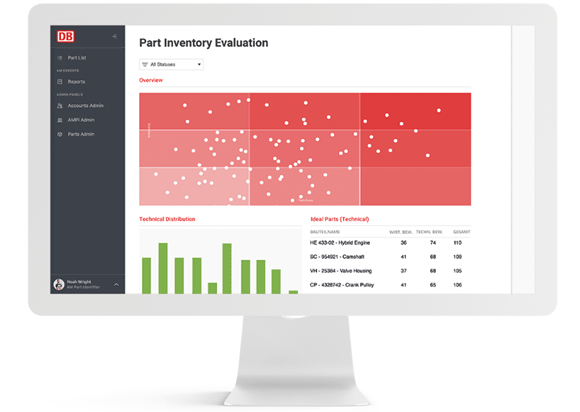

In an example of how 3YOURMIND can assist in this process, the company explains how Deutsche Bahn adopted its AM workflow software to centralise its data and identify parts for transition to the digital warehouse. Through this process, Deutsche Bahn reportedly increased its knowledge of Additive Manufacturing and transitioned a range of new parts to AM, improving its bottom line.