3D Lab launches ATO One for small-scale metal powder atomisation

October 19, 2017

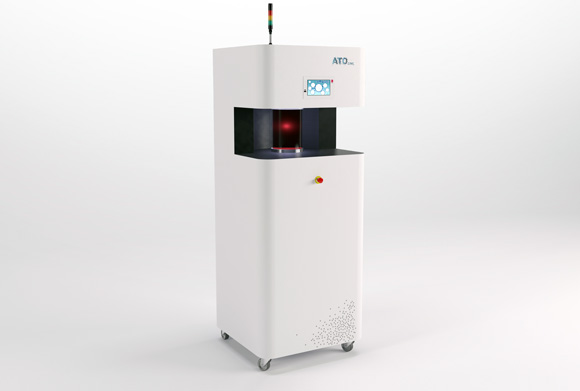

The ATO One is designed to fit in a small office or laboratory (Courtesy 3D Lab)

3D Lab Sp. z o.o, Warsaw, Poland, will launch what it says is the world’s first office-scale metal powder atomisation system at formnext powered by tct, Frankfurt, Germany, November 14-17, 2017. According to the company, the ATO One system is designed to satisfy the need for low cost, small-scale equipment for metal powder production in the field of Additive Manufacturing, isostatic pressing and conventional Powder Metallurgy.

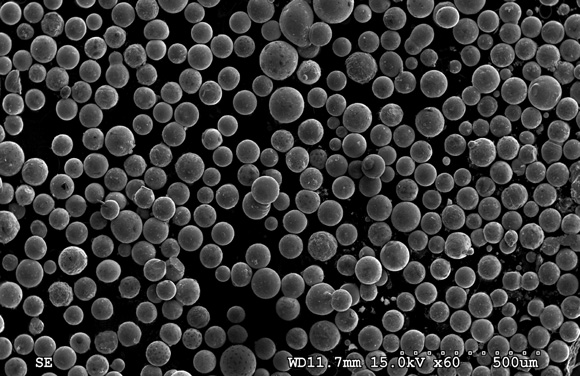

The atomiser is aimed primarily at SMEs, scientific institutions and powder producers for the development of novel materials. It is capable of processing reactive and non-reactive metals such as titanium, magnesium and aluminium alloys, and will produce powders with medium grain sizes in the range of 20-100 μm with a narrow grain size distribution. According to its designers, powder can be produced in small batches of several hundred grams per process.

Powders produced using the ATO One atomising system, as seen through an electron microscope (Courtesy 3D Lab)

By making it possible for organisations to atomise metal powders on a small-scale in-house, ATO One has the potential to reduce the need to employ external subcontractors for powder atomisation during R&D and other low-volume operations. This could make it quicker and more affordable for companies to develop their own novel materials, facilitating a wider diversity of materials and a higher degree of user control over raw material processing.

3D Lab has over ten years of experience in Additive Manufacturing, focused on the delivery and maintenance of professional and production-oriented AM devices. Beginning its research in the field of atomisation three years ago, the company reports that it quickly identified the need to rapidly produce small quantities of metal Additive Manufacturing feedstock for AM research and process parameters selection, having found the range of commercially available powders to be limited, with long-realisation times for small powder orders and high raw material costs.

3D Lab will display the ATO One atomiser on Booth 3.0-A74 at formnext. The first devices are expected to be dispatched in the third and fourth quarter of 2018.