Velo3D ships first Sapphire XC metal AM machine to aerospace customer

January 4, 2022

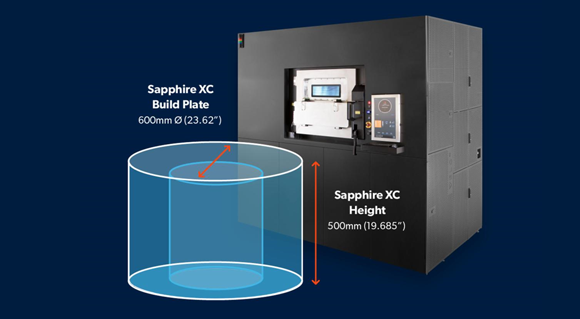

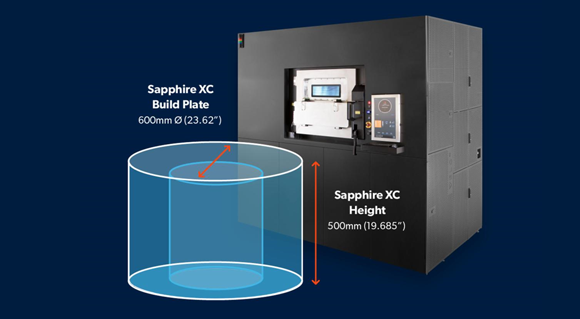

Velo3D, Inc, headquartered in Campbell, California, USA, has made the first delivery of its Sapphire® XC metal Additive Manufacturing machine. The XC, or ‘Extra Capacity’, is Velo3D’s largest metal AM machine and is a scaled-up version of the company’s Sapphire system, utilising the same Flow™ build preparation software, Assure™ quality control software, and Intelligent Fusion® manufacturing process.

The Sapphire XC is designed to enable a seamless transition of parts that were developed and qualified on the smaller Sapphire, reducing the cost of production by up to 75%. Sapphire XC also expands the use of Velo3D’s technology to parts that are up to 400% larger in volume than the those possible with Sapphire, explained Velo3D.

“I believe that the Sapphire XC will quickly become the gold standard in advanced metal Additive Manufacturing,” stated Benny Buller, Velo3D CEO and founder. “Because our customer is already utilising our end-to-end production solution, they can immediately and seamlessly move parts to Sapphire XC to achieve a phenomenal production rate increase. We made a huge effort to ensure that Sapphire XC uses the exact same manufacturing process as Sapphire. The ability to move production seamlessly between different products was considered impossible when we started Velo3D, but I am proud to declare that we have unlocked this ability for our customers and partners. It is a huge accomplishment — our biggest achievement of 2021.”

Velo3D currently has a backlog of firm orders for seventeen additional Sapphire XC systems, as well as nineteen additional reservations. The company states that demand is primarily driven by the lower production costs that Sapphire XC can offer customers who have adopted the original Sapphire AM machines. The improvements are largely driven by new features and capabilities that include including larger build volume, additional lasers and faster non-contact recoater.

The Sapphire XC is able to additively manufacture a wide variety of materials that are often used in the production of mission-critical parts in the aviation, aerospace, defence, oil and gas, and energy industries. These include Inconel 718 & 625, Hastelloy® X, Hastelloy® C22, aluminium, Scalmalloy©, and titanium Ti-6Al-4V.