CoreTechnologie adds Nastran interface to 4D_Additive update

January 5, 2022

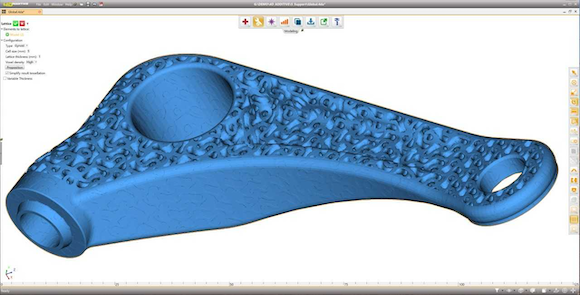

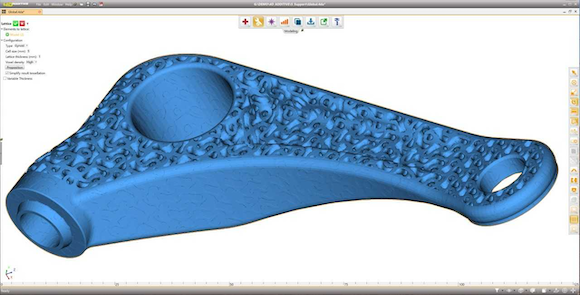

In the latest version of the Additive Manufacturing software 4D_Additive, CoreTechnologie, headquartered in Mömbris, Germany, has added a Nastran interface which is intended to allow for the quick creation of diverse lattice structures and convert these structures, as well as other alternative part designs, to the calculation software within seconds.

The 4D_Additive software provides tools intended to simplify the creation of twenty different 3D lattice structure types. CAD solids can be filled with internal structures and can also be replaced by external structures. In particular, gyroid patterns and trabecular structures to emulate natural lattices (such as those found in bones) are used to generate new designs to optimise the weight, stability, stress distribution and shock absorption of components.

The use of different lattice types and the variation of the density and cell size over the course of the component allows the adaptation of the geometry to the required properties with optimised component properties. In contrast to topology optimisation, this approach optimises designs iteratively, and can be validated with simulation tools on the fly.

The updated 4D_Additive with Nastran interface is expected to be released in early 2022.