Additive Industries presents new MetalFABG2 AM machine series at Formnext

November 16, 2021

At Formnext 2021, Additive Industries, Eindhoven, the Netherlands, has presented its new MetalFABG2 series metal Additive Manufacturing machine along with a number of AM solutions that include MF Calibrate, for automated multi-beam qualification, and Additive Studios, offering a variety of professional services. Partnerships with Makino, Sigma Labs and Materialise were also announced.

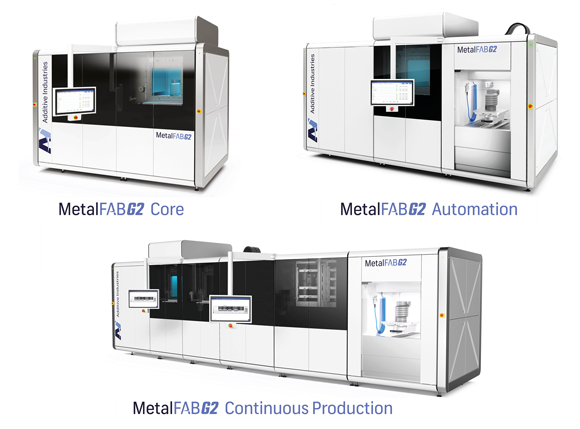

Additive Industries explained that the new MetalFABG2 series doubles productivity, compared to previous models, and includes over 150 updates. It features optimised gas flow, optimised heat management, updated process parameters and automated beam quality measurements. The AM machine is Sigma Labs PrintRite3D ready and is available in three versions: Core, Automation and Continuous Production.

The MF Calibrate is a multi-beam qualification tool to ensure repeatable and predictable output. The tool automates the procedures for each beam, saving precious time. A normal manual procedure for beam quality validation for multi-laser systems can take up to a day. With this tool, it reportedly takes less than an hour.

From its offices in Bristol, UK; Los Angeles, USA; Eindhoven and Singapore, Additive Industries offers services in the field of applications, design for AM, optimising build strategies, process parameters and material development, production optimisation and post-processing methods.

Additive Industries’ partnership with Sigma Labs to realise PrintRite 3D integration of Melt pool monitoring (Beta). PrintRite3D® is a real-time melt pool analytics and monitoring solution that reduces waste, improves throughput and enables faster product development and part qualification. With the use of in-process meltpool monitoring, it is easier to analyse additively manufactured parts by reducing or completely avoiding post analysis using destructive testing or CT scanning. This integration is especially interesting for large and massive parts, giving indications of potential errors during production. It may become part of future qualified production processes, automating the quality control per part.

Additive Industries partnered with Materialise to develop workflow improvements, which included an update of the Build Processor, V2.6. It is now capable of slicing bigger data and offers double faster processing. Furthermore, this version is capable of processing e-Stage-support by creating e-stage on slicing and is optimised for use with the Additive Industries Dynamic Laser Assignment Tool. In addition, Additive Industries entered a partnership with Makino, a machinery equipment manufacturer and digital innovation specialist, to develop end-to-end AM solutions.

“We are excited to launch this broad array of new solutions and services, which underline our ambition to provide the next generation in productivity leadership,” stated Ian Howe, CEO at Additive Industries. “One of the most exciting aspects of Additive Manufacturing is the versatility of the technique. Applications can be found in almost every industry, in parts that range from simple brackets to complex assemblies with moving parts and many integrated functions. With our services and solutions, we ensure our partners are able to utilise AM to the fullest.”